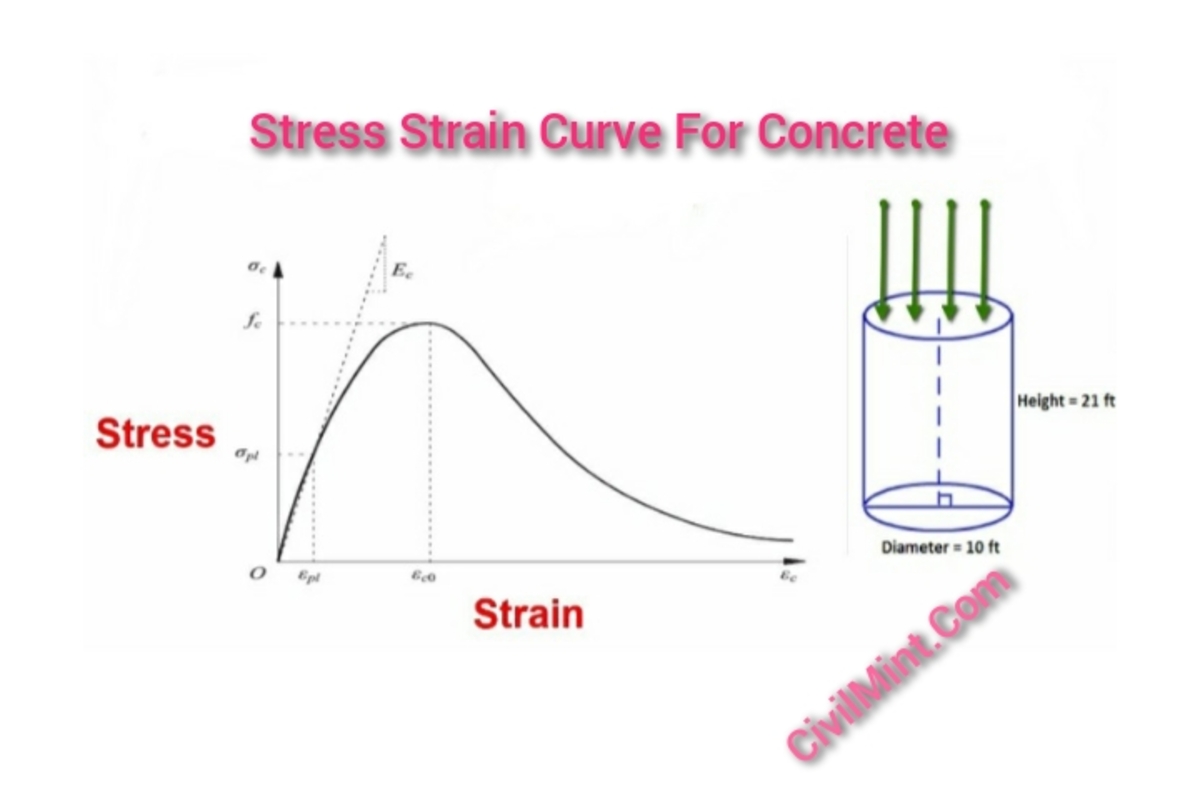

Stress Strain Curve For Concrete

Stress strain curve for concrete is used to understand and predict the behavior of concrete under various loading conditions. It is a graphical representation of the relationship between the stress applied to a concrete material and the resulting strain (deformation) that occurs.

The stress-strain curve for concrete is typically divided into three distinct regions: the linear elastic region, the transition region, and the plastic region.

In the linear elastic region, the relationship between stress and strain is linear, and the concrete behaves as a linear elastic material. The slope of this region is known as the Young’s modulus, which is a measure of the concrete’s stiffness. The linear elastic region is where the concrete can withstand a certain amount of deformation and still return to its original shape once the load is removed.

As the stress applied to the concrete material continues to increase, the stress-strain curve begins to deviate from linearity in the transition region. In this region, the concrete begins to strain beyond its elastic limit and starts to exhibit plastic deformation. The amount of plastic deformation that occurs in this region depends on various factors such as the type of concrete, curing process, and the presence of cracks or defects in the material.

In the plastic region, the concrete deforms plastically, and the stress-strain curve levels off. This indicates that the concrete is no longer able to withstand additional stress and is approaching failure. The maximum stress that can be applied to the concrete before it fails is known as its compressive strength. The compressive strength is an essential property of concrete, as it determines the load-bearing capacity of the material.

It’s important to note that the shape of the stress-strain curve can vary depending on several factors such as the type of concrete used, the mix design, the curing process, and the presence of defects or cracks in the material. For example, the stress-strain curve for high-strength concrete would differ from that of low-strength concrete.

Understanding the stress-strain curve for concrete is crucial in designing and constructing safe and durable structures. Engineers use the curve to predict the behavior of concrete under various loads and conditions, and design structures that can withstand these loads. It is also useful in assessing the quality of concrete, identifying any defects or weaknesses in the material, and ensuring that the material meets the necessary standards and specifications.

Faqs

The stress-strain curve of concrete is influenced by factors such as water-cement ratio, curing, aggregate size/type, and additives.

The non-linear stress-strain curve of concrete is crucial for determining its structural behavior. It can withstand stress initially, but as stress increases, it becomes non-linear, causing deformation, cracking, and possible failure of the structure.