Table of Contents

What Is Track Bed?

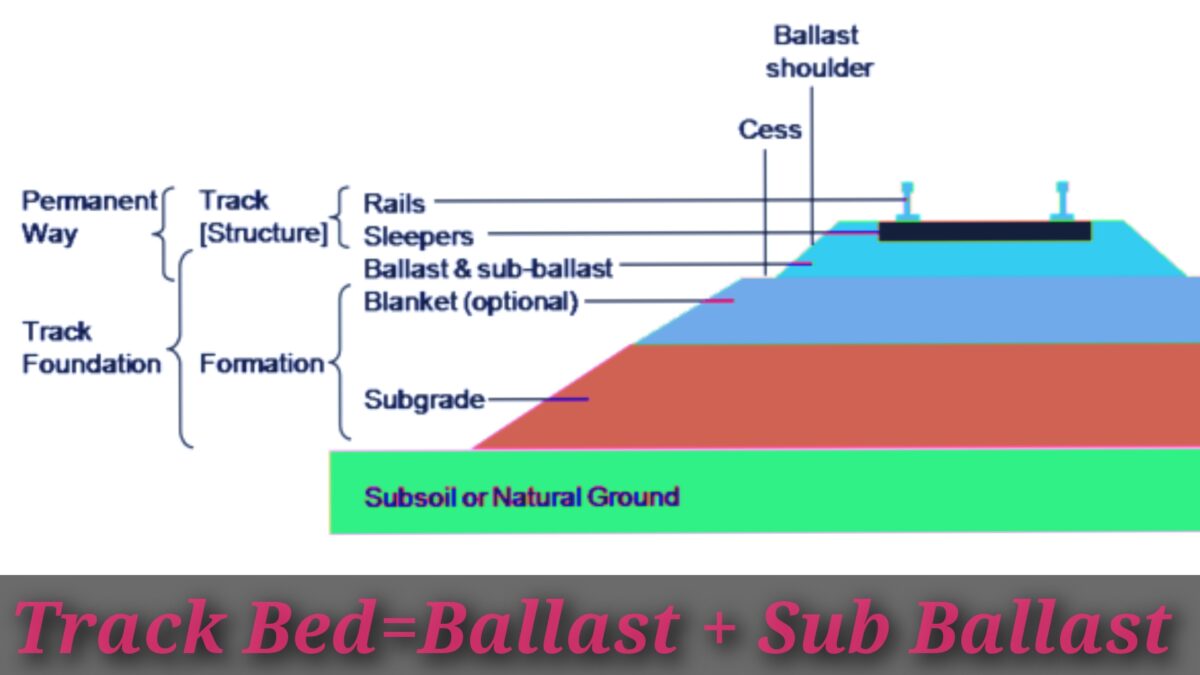

The track bed, also known as the trackbed, is the foundation or base on which a railway track is built. It serves as the support system for the tracks and plays a crucial role in ensuring the smooth and safe operation of trains.

Track Bed = Ballast + Sub-Ballast

The track bed consists of multiple layers that are carefully constructed to provide stability and proper drainage. The bottom layer is called the subgrade, which is the natural ground or soil. On top of the subgrade, there are layers of materials that are placed to form the track bed.

The main layers of the track bed are the ballast and sub-ballast. The ballast is made up of crushed stones or gravel and is laid directly on top of the subgrade. It provides a stable surface for the tracks, helps distribute the weight of the trains, and allows for proper drainage of water.

Above the ballast, there may be a layer called the sub-ballast. This layer consists of coarser material and further enhances the stability of the track bed. Additionally, depending on the specific design and requirements, there may be other elements like geotextiles or drainage systems incorporated into the track bed.

The track bed is essential because it helps maintain the alignment of the tracks, prevents excessive movement, and supports the weight of the trains. It also allows water to drain effectively, preventing water accumulation that could lead to track instability or damage.

The quality of the track bed has a significant impact on the performance of the railway. A well-constructed and maintained track bed ensures smoother rides for passengers and reduces the risk of track deterioration.

Importance Of Track Bed

Track beds evenly distribute the weight of trains, locomotives, and rolling stock across a large surface area, preventing excessive stress on the tracks.

A well-designed and maintained track bed ensures stability, reducing track settlement, lateral movement, and the risk of derailments.

Track beds facilitate efficient drainage, preventing water accumulation and maintaining optimal track resilience under varying weather conditions.

Composition Of Track Bed

1. Ballast:

The primary component of track beds is ballast, typically made of crushed stone or gravel.

Ballast provides support, drainage, and resistance to track movement.

2. Sub-ballast:

In some cases, a layer of sub-ballast may be added beneath the main ballast to enhance load distribution and improve drainage characteristics.

Construction Of Track Bed

1. Site Preparation:

The construction process begins with site clearance, excavation, and the removal of organic materials to create a level and stable foundation.

2. Subgrade Preparation:

The subgrade is carefully graded and compacted to achieve the required strength and stability.

3. Ballast Placement:

The ballast is evenly distributed and compacted to the specified depth and profile, using specialized machinery such as ballast tampers and regulators.

4. Track Alignment and Tamping:

Tracks are aligned and leveled using lasers and other precision instruments, followed by tamping to ensure proper compaction and stability.

Track Bed Maintenance

We regularly tamp and stabilize the track bed to keep it strong and stable. This helps the track stay straight and evenly distribute weight.

Having good drainage is important to prevent water from collecting and making the track soft and unstable. We regularly check and maintain the drainage systems to keep them working well.

Over time, the ballast can get dirty and less effective. To keep the track in good shape, we clean the ballast and sometimes replace it.

Plants growing out of control can cause problems with drainage, stability, and visibility. We take care of the plants regularly to make sure the track lasts a long time

Sum Up

Track beds play a crucial role in railway infrastructure by providing stability, load distribution, and drainage capabilities.

Construction techniques and regular maintenance ensure their longevity and safety. Innovations in track bed technology, such as geosynthetics, ballastless track systems, and intelligent monitoring, continue to enhance the performance and efficiency of railway networks.

As the railway industry evolves, track beds will continue to be fundamental in ensuring safe and reliable transportation for passengers and freight.

Faqs

Crushed stones or gravel called ballast are used in a track bed. They are hard and strong to make the tracks stable.

During extreme weather like heavy rain or snow, the track bed needs special care. Drainage is checked to prevent water buildup, and snow is cleared from the tracks. In very hot weather, special measures are taken to prevent the tracks from bending.

Yes, the materials used in the track bed can be recycled or used again. When tracks are replaced, the old ballast can be cleaned and reused in new tracks or other construction projects.

There are signs that show if the track bed is getting worse. The tracks may become uneven or sink, there might be lots of shaking, water can collect on the tracks, and maintenance needs increase. Regular checks help find these problems early and fix them.

Yes, there are other things being used or tested for track bed construction. Some use concrete instead of ballast, and there are new technologies like slab tracks made from special materials. These alternatives are more stable and need less maintenance.