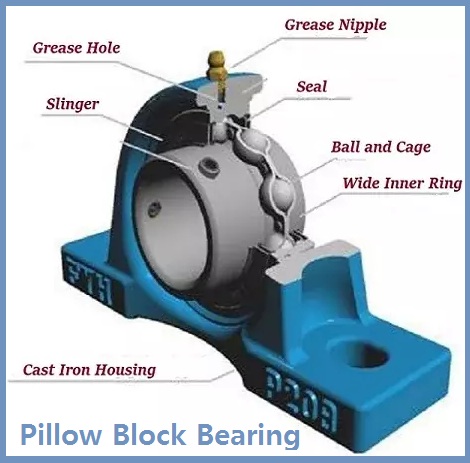

Pillow block bearing provides support to the rotating shaft. A rotating shaft is put inside the pillow block. The bearing is placed inside the pillow block. Pillow block bearing is also known as a Plummer block.

Pillow block bearings are most commonly used in low torque applications. Bearing bases or leg slots or holes make assembly and adjustment easy.

Pillow blocks typically incorporate rolling bearings in which the mounted shaft is parallel to the mounting surface and in a plane perpendicular to the centerline of the mounting holes, in contrast to various types of flanged blocks or units. Refers to the housing. Pillow block bearings can include bearings with one of several types of rolling elements, such as balls, cylindrical rollers, spherical rollers, tapered rollers, and metal or synthetic bushings.

Table of Contents

Types of Pillow Block Bearings

Five major types of pillow block bearing are commonly used in industrial applications.

- Plain Bearing

- Ball Bearing

- Roller Bearing

- Needle-roller Bearing

- Hydrodynamic Bearing

Let’s have a look at the types of pillow block bearings.

1. Plain Bearing

Plain bearings are most commonly used in linear applications, limiting movement, guiding, and reducing friction. These bearings use slide motion instead of the rolling motion used in needle bearings, roller bearings, and ball bearings. Various materials such as plastic, graphite metal, and bronze are used in the construction of plain bearings. Metal plain bearings need to be properly lubricated to reduce friction and wear.

2. Ball Bearing

Ball bearings contain balls. These types of pillow blocks are used in spinning applications to provide low friction and smooth movement. Ball bearings include cages, balls, outer rings, and inner rings. These bearings also have a ball separator instead of a cage.

3. Roller Bearing

Rolling bearings contain rollers instead of balls as rolling elements. These bearings are also used in spinning applications to reduce friction and provide smooth movement. The structure of this bearing includes inner and outer rings, rollers, and roller separators or cages.

4. Needle-roller Bearing

They use needle rollers as rolling elements. These bearings have a structure very similar to cylindrical roller bearings. However, needle roller bearings have a smaller diameter-to-length ratio than cylindrical roller bearings. By adjusting the circumferential clearance between the needles, the rolling elements remain parallel to the shaft axis. These bearings are designed for radial loads that require a low profile.

5. Hydrodynamic Bearing

They are oil film bearings. They rely on air or oil slicks to create a clearance gap between the stationary and rotating elements. Low load capacity, long service life, and high rigidity. However, it is more complex and costly than standard roller bearings.

Uses of Pillow Block Bearing

These units are extremely versatile and can be used in a variety of applications. They range from single bearing shafts to multiple bearing units. Example:

- Belt drive connecting motor and pump

- A long shaft connecting the motor and the industrial gearbox

- Conveyor roller

- Rolling machine

- Ventilation system

- Paper machine