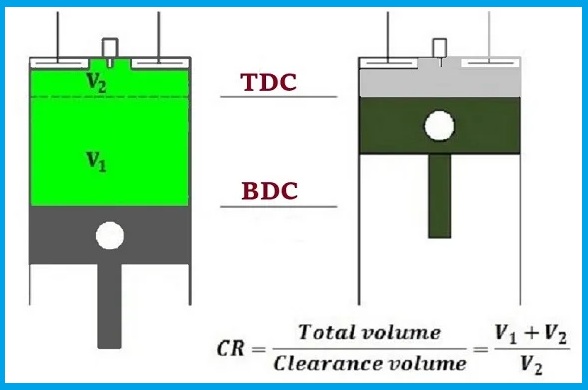

The compression ratio of an internal combustion engine is the ratio of the maximum and minimum values of the engine cylinder and combustion chamber. The ratio of the total volume of the combustion chamber that remains when the piston is in the BDC to the volume that remains in the combustion chamber when the piston moves to the TDC is called the compression ratio.

Table of Contents

Types of Compression ratio

The compression ratio is calculated using two different methods:

- Static Compression Ratio

- Dynamic Compression Ratio

Let’s take a look at these 2 types of compression ratios.

1. Static Compression Ratio

The static compression ratio is measured according to the volume of the combustion chamber when the piston is at the top stroke and the relative volume of the combustion chamber and cylinder when the piston is at the bottom of the stroke.

2. Dynamic Compression Ratio

Dynamic compression ratio is difficult to calculate because it also includes air entering and leaving the cylinder during compression.

Imagine an engine with an aggregate displacement of 2000cc. In this 2000cc, 1900cc is the swept volume (the distance traveled by the piston as it moves from BDC to TDC), and the clearance volume is 100cc (the volume left in the cylinder when the piston reaches TDC). Hence, the Compression Ratio of this engine is 2000:100 or 20:1.

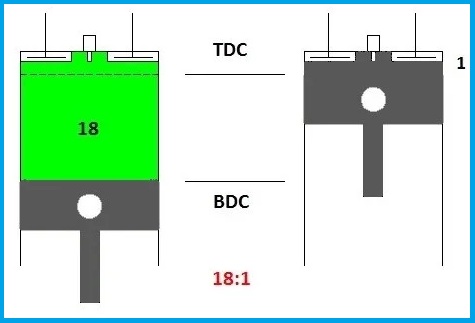

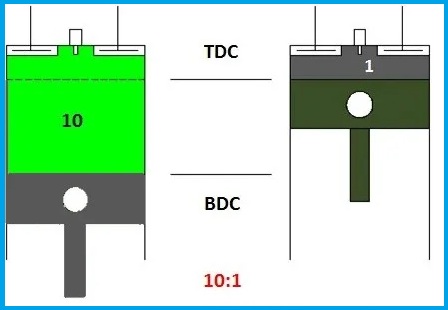

Engine efficiency is increased by increasing the compression ratio. As you know, the diesel engine doesn`t contain a spark plug, and the ignition process occurs due to the high compression of the air-fuel mixture. Therefore, the diesel engine compression ratio (18:1 to 23:1) is higher than the petrol engine compression ratio (10:1 to 14:1).

Factor Affecting Design Criteria of Compression Ratio

- Stroke length

- Bore Diameter

- Square Engine

- Number of Cylinders

The Compression Ratio of Petrol Engine

The compression ratio of a four-stroke gasoline engine is given below:

- As everyone knows, the gasoline engine sucks the air-fuel mixture during the intake stroke.

- During compression, the air-fuel mixture is compressed so that it mixes and burns properly.

- Gasoline engines need the correct compression ratio for the air-fuel mixture to ignite the fuel-air mixture appropriately and provide better thermal efficiency.

- During compression, the pressure and temperature of the air-fuel mixture in the cylinder increase, causing the fuel to burn completely or normally when the spark plug ignites, which improves fuel economy and prevents the Engine burned wrong.

- Gasoline engines with just enough CR provide balanced power and speed.

- The latest petrol engines typically have a compression ratio of 10.0:1 to 13.5:1.

- The CR of an engine with a knock sensor is typically greater than 11.1:1 and close to 14.0:1 (typically for high octane fuel and direct fuel injection), but the CR of a petrol engine without a knock sensor is typically 8.0:1 to 10.5:1.

The Compression Ratio of Diesel Engine

- Diesel engines do not have spark plugs to burn the air-fuel mixture. Therefore, a high CR is required to properly burn the air-fuel mixture. Therefore, fuel combustion is entirely dependent on air compression during the compression stroke of the diesel cycle.

- Diesel engines with high compression ratios compress air highly, so the temperature of the compressed air must be raised to the temperature at which the self-ignition temperature of the fuel is injected. This will burn the fuel completely or properly.

- Diesel engines have a higher compression ratio than gasoline engines.

- Diesel engines produce high output due to the high CR of the diesel engine.

- As you know, the higher the CR, the higher the thermal efficiency or output power. High CR diesel engines provide excellent fuel economy because of the increased thermal efficiency of high compression combustion. Diesel engines typically have a compression ratio of 18: 1 to 23: 1, depending on the engine design and application type.