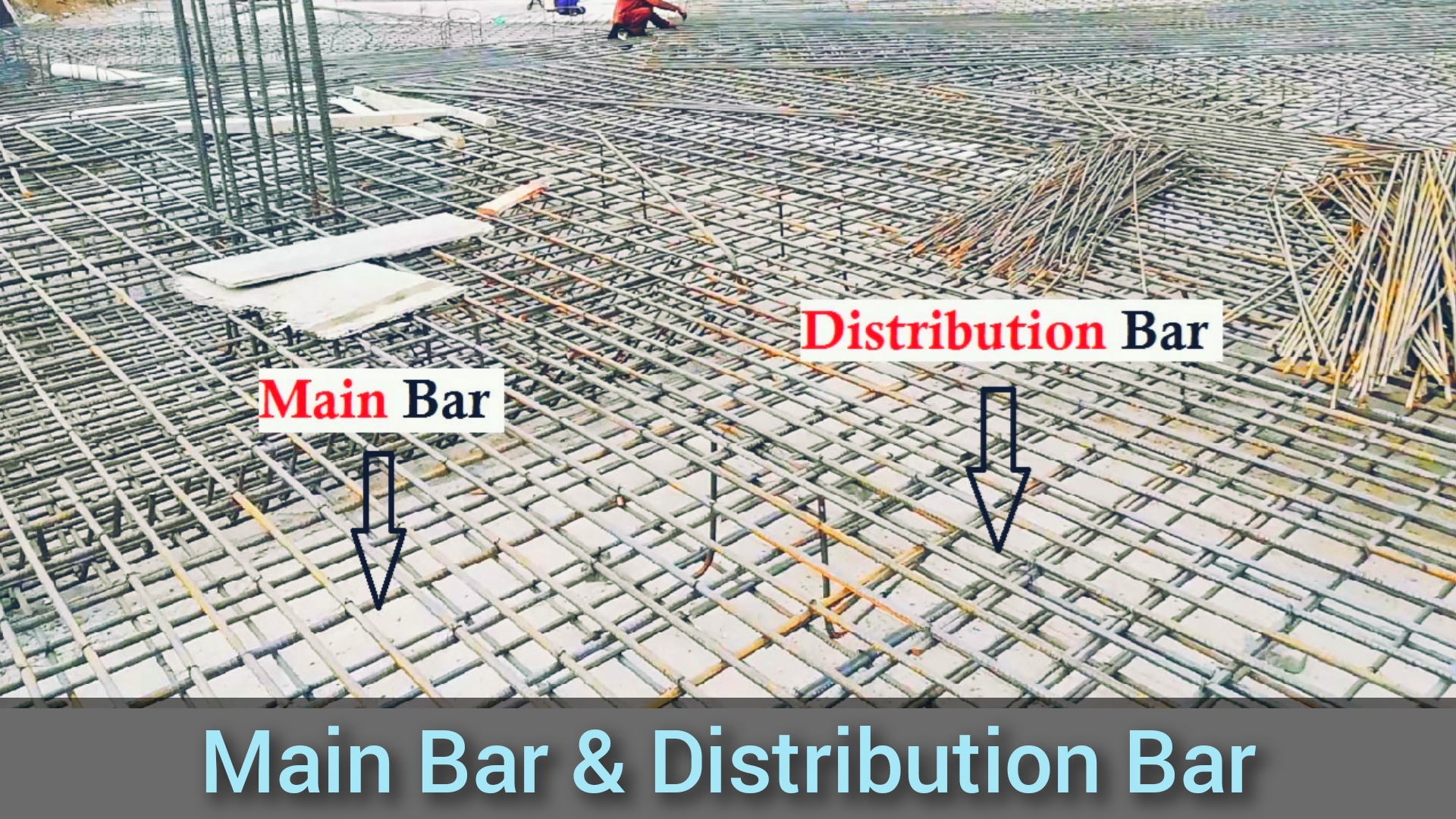

In this article, I will explain difference between Main Bar and Distribution Bar in Reinforcement Concrete slab.

Normally, there are two types of reinforcement bars are provided in the construction of the Reinforced Concrete slab.

1. Main Reinforcement Bar.

2. Distribution Reinforcement Bar.

Table of Contents

Main Bar And Distribution Bar

Check out the below table to understand main bar and distribution in reinforced concrete slab.

| # | Main Bars | Distribution Bars |

|---|---|---|

| 1 | Placed parallel to one direction | Placed perpendicular to main bars |

| 2 | Carries the main load of the structure | Carries a small portion of the load |

| 3 | Larger in diameter and spacing | Smaller in diameter and spacing |

| 4 | Typically placed at the bottom of the slab | Typically placed at the top of the slab |

| 5 | Required in both directions for two-way slabs | Only required in one direction for one-way slabs |

| 6 | Usually placed at a spacing of 100-200mm | Usually placed at a spacing of 200-300mm |

| 7 | Provides strength to the slab in the direction of placement | Provides strength to the slab in the transverse direction |

| 8 | Usually made of high-yield steel | Usually made of mild steel |

| 9 | Requires more steel and concrete | Requires less steel and concrete |

| 10 | Usually placed first during construction | Placed after the main bars are placed |

| 11 | Typically continuous throughout the slab | May be interrupted or discontinuous |

| 12 | Spans the entire width of the slab | Only spans a portion of the slab width |

| 13 | Designed to resist bending and shear forces | Designed to resist shear forces only |

| 14 | Usually placed at a depth of 25-50mm from the bottom of the slab | Usually placed at a depth of 15-25mm from the top of the slab |

| 15 | Provides rigidity and stability to the slab | Helps to distribute the load evenly across the slab |

| 16 | Must be properly anchored at the support | Not required to be anchored at the support |

| 17 | Helps to prevent cracking due to shrinkage and temperature changes | Helps to prevent cracking due to bending and shear forces |

| 18 | Required to be tied to each other and to the main bars | Not required to be tied to each other or to the main bars |

| 19 | Designed to resist tension forces | Designed to resist compression forces |

| 20 | May be straight or bent | Usually straight |

| 21 | Mainly placed in the longer span direction | Placed in the shorter span direction |

| 22 | Provides resistance against the forces produced by the dead load | Provides resistance against the forces produced by the live load |

| 23 | The number of bars required depends on the size of the span and the loads | The number of bars required depends on the spacing and the loads |

| 24 | The spacing between bars is uniform | The spacing between bars may vary |

| 25 | Usually have hooks at the ends for anchoring | Ends may be straight or bent |

| 26 | Designed to resist the tensile force in the longitudinal direction | Designed to resist the shear force in the transverse direction |

| 27 | Normally thicker in diameter | Normally thinner in diameter |

| 28 | Sometimes called longitudinal reinforcement | Sometimes called transverse reinforcement |

| 29 | May be required to be pre-stressed | Not required to be pre-stressed |

| 30 | Used to create a strong, continuous structure | Used to distribute the load evenly across the slab and prevent cracking |

Wht Is Main Bar In Reinforced Concrete Slab?

The reinforcing steel bars placed in the bottom layer of the reinforced concrete slab are known as the main bars.

The main bars provide tensile strength to the slab and help resist bending and cracking under load.

Engineers calculate the required spacing, diameter, and quantity of main bars to ensure the slab can withstand the loads it will be subjected to over its lifespan.

The main bars are typically larger in diameter and closer together than the bars used in the upper layer of the slab.

The design of the main bars is critical to the strength and stability of the reinforced concrete slab.

What Is Distribution Bar In Reinforced Concrete Slab?

Engineers place distribution bars in reinforced concrete slabs to evenly distribute loads.

The reinforcement bars perpendicular to the main bars resist shear forces and prevent cracking.

The design requirements dictate the size and spacing of the distribution bars.

Contractors must follow the specifications for the placement and size of the distribution bars during construction.

The correct depth and spacing of distribution bars ensure proper load distribution and prevent structural damage.

Functions of Main Reinforcement Bars In A Slab:

- The Main bar is to be provided at the shorter span of the slab. The shorter span slab faces a High bending Moment which is called a sagging or positive bending moment.

- Main reinforcement bars resist the tensile stresses, bending moment (Sagging), and superimposed load (Dead load) which developed at the shorter span of the slabs.

- Main reinforcement bars are provided in one way slab in one direction (At a shorter span), but in the two-way slab, bars are provided in both ways.

- In the Flat-plate slabs, the main bars are provided in one direction at bottom of the distribution bar (in a shorter span).

- Main bars in the slabs should not be less than 8 mm if you are using the H.Y.S.D bar or 10 mm if you are using Plain bars.

Functions of Distribution Bars In A SLAB:

- Distribution bar is to provide at the long span of the slab.

- Distribution bar is designed to distribute the superimposed load equally or counter the shrinkage stresses which are developed because of temperature variation (Winter, Summer).

- In the flat-plate slab, the distribution bars are provided in one direction at top of the main bar along the longer span.

- The distribution bars should not be less than 8 mm in diameter or not be more than 1/8 of the thickness of the R.C.C slabs.

- The distribution bars are provided to hold the mesh in position and maintain the center to center spacing between main bars.

Difference between Main Bars and Distribution Bars:

☑ The Main bars are provided at the bottom of the distribution bar in slabs while Distribution bars are provided on the top of the main bar.

☑ The Main bars are provided along the shorter span of the slabs while Distribution bars are provided along the longer span of the slabs.

☑ The Main bars are provided to resist the bending moment, tensile stresses, and superimposed load while Distribution bars are utilized to distribute the load equally, resist the shrinkage stress (Temperature difference) or hold the steel mesh in the right position.

☑ Main bars in the slab should not be less than 8 mm if you are using H.Y.S.D or 10 mm if you are using Plain bars and the

☑ Distribution bars should not be less than 8 mm in diameter and the bar should not be more than 1/8 of the thickness of the slab.