Table of Contents

What is Drum Brake?

A drum brake is a brake that uses friction created by a series of shoes or pads that push outward on a rotating cylindrical part called the brake drum. Drum brake is the most common type of brake used the vehicles.

The term drum brake usually refers to brakes in which the shoe presses against the inner surface of the drum. When the shoe pushes against the outside of the drum, this is commonly called a clamp brake.

Like traditional disc brakes, when the drum is clamped between two shoes, it is sometimes called a clamped drum brake, but such brakes are relatively rare. A related type called a band brake uses a flexible belt or “tape” that wraps around the outside of the drum.

Structure of Drum Brake

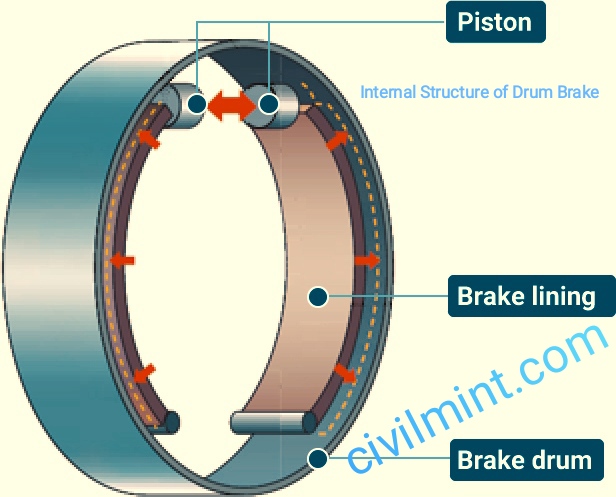

A drum brake is a braking system with a brake drum that rotates with the wheel. Inside each drum are brake shoes with brake pads. A piston pushes the drum from the inside to generate a braking force that decelerates and stops the vehicle.

Parts of Drum Brake

Parts of drum brake are listed below.

- Drum

- Backing Plates

- Brake Shoes

- Anchor

- Adjuster

- Expander

In the below figure I have shown the parts of drum brake.

Let’s read in detail about various parts of drum brake.

1. Drum:

The drum mounts concentrically to the axle hub and the back plate mounts to the axle housing.

2. Backing Plates:

Made of pressed steel for added rigidity and support for expanders, anchors and brake shoes. It is ribbed for It also protects the drum and shoe from dirt and dust. This plate is sometimes called a torque plate because it absorbs the entire brake shoe torque response.

3. Brake Shoes:

A key component of any braking system. There are two pairs of his shoes fixed to the backplate. The shoe is fitted with a friction lining. There are two types of brake shoes, depending on the braking force. The first is the leading type and the other is the trailing type.

Lead Shoe: A lead shoe that tends to brake or drag along the drum due to its centrifugal action when the brake is not applied is called a lead shoe. When braking, the net force applied to the leading shoe is greater than the other shoes.

Trailing Shoe: A shoe that tends to come off the drum due to own rotation is called a trailing shoe. The net force on the trailing shoe is less than the leading shoe.

4. Return Spring:

This spring is used to keep the brake shoe away from the drum when the brake is in the released position.

5. Anchor:

The brake shoe is fixed at one end and free at the other end. A force is applied to the free end to apply a braking force.

6. Adjuster:

Install between the fixed ends of the brake shoes. It is used to adjust the fixed distance between the drum and the shoe or to compensate for friction lining wear.

7. Expander:

This is a cam or rocker arm that attaches to the backplate and is used to apply braking force when needed. Expanders can be fixed or floating.

How Drum Brakes Work

In the below figure I have shown the working of drum brake.

When the driver presses the brake pedal, the force is amplified by the brake booster (servo system) and converted to hydraulic pressure (hydraulic pressure) by the master cylinder. The pressure reaches the wheel brakes through hoses filled with the brake he oil (brake fluid). The released pressure pushes the brake pistons of the four wheels. The piston presses the brake pad, which is a friction material, against the inner surface of the brake drum, which rotates with the wheel. The pads press against the rotating drum, braking the wheels and slowing the vehicle to a stop.

Types of Drum Brake

There are 4 types of drum brakes as listed below.

- Fixed expander type

- Floating expander Type

- Two-guide shoe type

- Two trailing shoes type

Let’s know more about these 4 types of brakes.

1. Fixed expander type

The brake shoes already described are of the fixed expander type or have a fixed expander position in this braking system. The major problem with this method is that if one brake shoe is a trailing type and the other is a leading type, the leading type has a higher braking force than the trailing type, so the friction material wears out faster. This creates an uneven braking force on the two shoes.

2. Floating expander Type

In this system, the expander is floating and adjusts its position according to the braking force of both shoes so that both shoes have the same braking force and the braking force of both shoes is balanced. take

3. Two-guide shoe type

This is a system that uses a fixed anchor and a floating anchor, and makes both shoes one-guide type. The main advantage of this type of braking system is the increased braking torque due to the excellent shoe quality.

4. Two trailing shoes type

This system also uses fixed and floating anchors. Since it is a shoe that reduces braking force, it is used in combination with power brakes and servo brakes. These braking systems have better fade resistance.

Advantages

- Slightly less maintenance

- Due to better corrosion resistance compared to the less expensive washer to manufacture

- Due to the built-in self-excitation effect, less input force is required.

- The wheel cylinder is a little easier to overhaul than the caliper.

- Minor weight reduction. This is mainly due to the much smaller and lighter hydraulic cylinder compared to the caliper.

Disadvantages

- Heating issues as all parts are enclosed in the drum itself. So when you apply the brakes, the heat generated between the brake shoes and the drum is trapped inside the assembly.

- Low efficiency due to thermal issues and shoe lining wear.

- If water collects in the assembly, the shoes will easily slide on the drum, reducing the effectiveness of this braking system.