Table of Contents

What Is Girder Bridge?

Girder bridge is a type of bridge in which girders are used to support the slab of the bridge. Girders are large span beams usually made of structural steel or reinforced cement concrete (RCC). Girder bridge is also known as beam bridge.

Types Of Girder Bridges

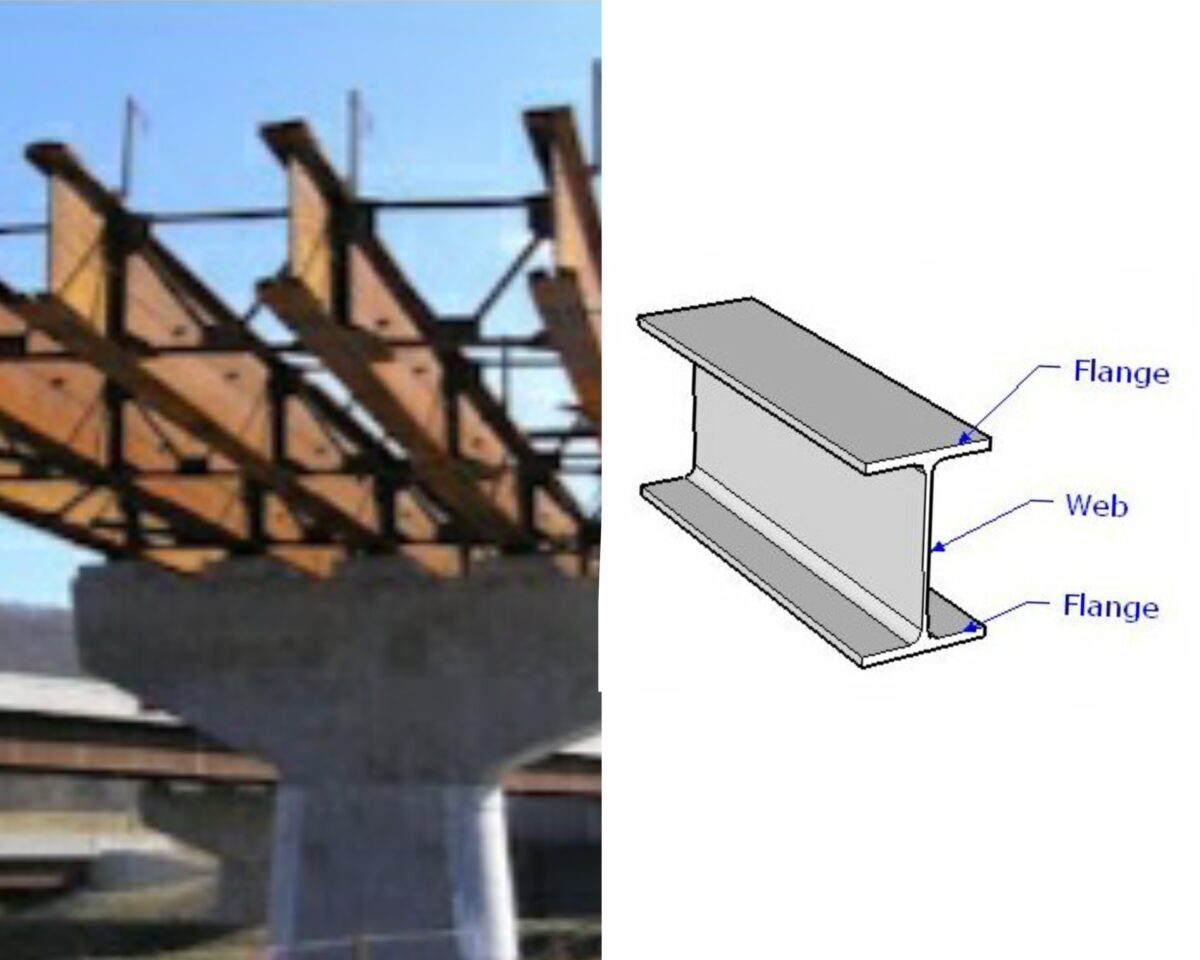

1. I-Beam Girder Bridge:

The I-beam girder bridge is one of the simplest and most widely used types. It consists of a series of I-shaped beams that are placed parallel to each other and connected by cross-members. This type of bridge is ideal for short to medium spans and is capable of carrying moderate loads.

2. Box Girder Bridge:

A box girder bridge, or box section bridge, is a bridge in which the main beam consists of girders in the shape of a hollow box. Box girders typically consist of prestressed concrete, structural steel, or a mixture of steel and reinforced concrete. The box is usually rectangular or trapezoidal in cross-section.

This type of bridge is commonly used for modern elevated structures of highway flyovers and light rail transportation. Although the box girder bridge is generally a form of beam bridge, box girder can also be used on cable-stayed and other bridges.

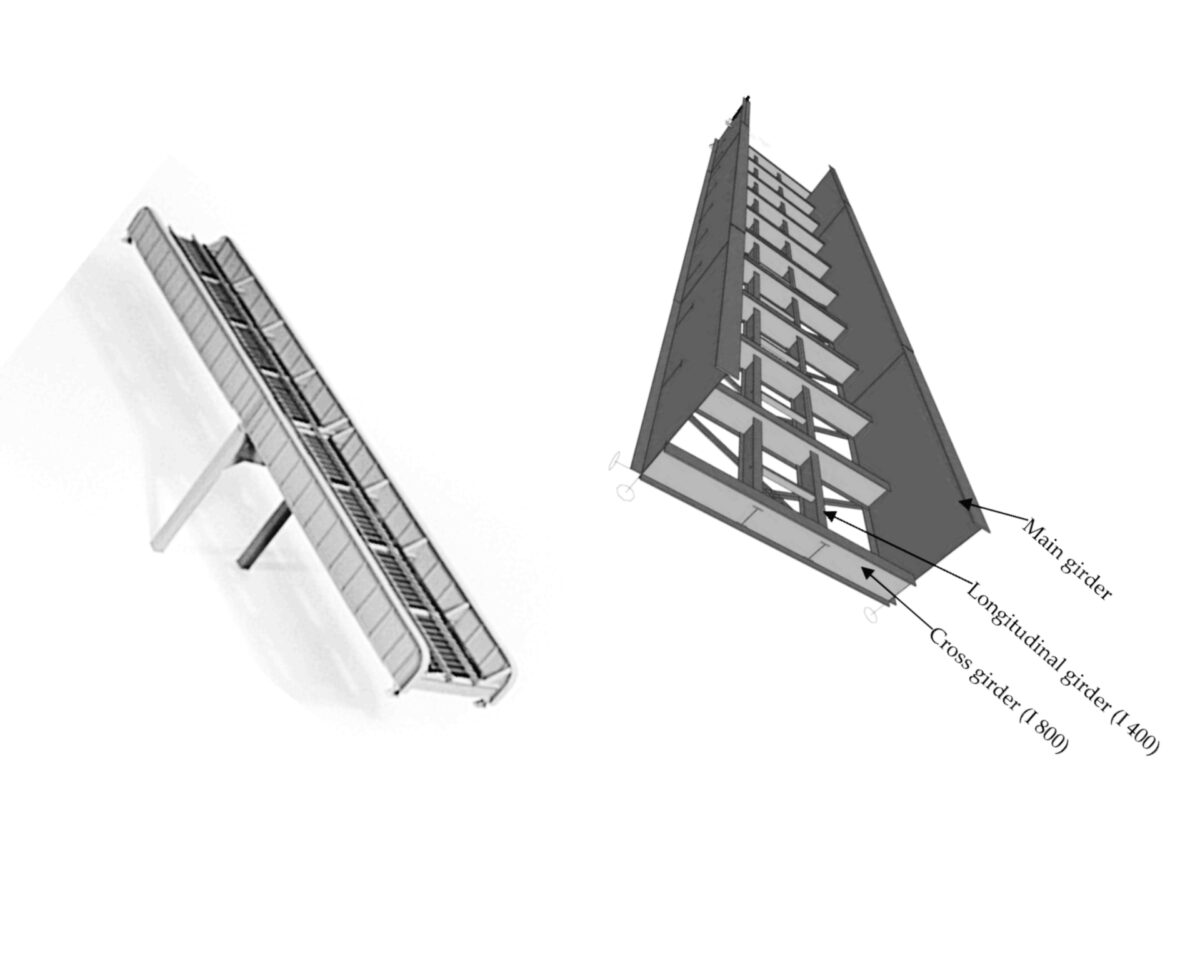

3. Plate Girder Bridge:

Plate girder bridges are constructed using welded or riveted steel plates. These plates are assembled to form a series of girders that support the bridge deck. Plate girder bridges offer versatility in design and are well-suited for various span lengths and load requirements.

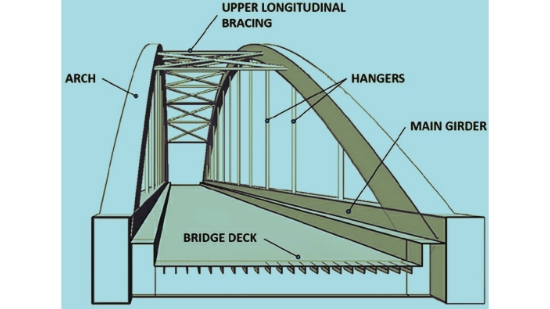

4. Tied Arch Girder Bridge:

Tied arch girder bridges combine the use of arches and girders to create a visually striking and structurally sound design. The arches provide support while the girders help distribute the load. Tied arch girder bridges are often used for river crossings and are known for their aesthetic appeal.

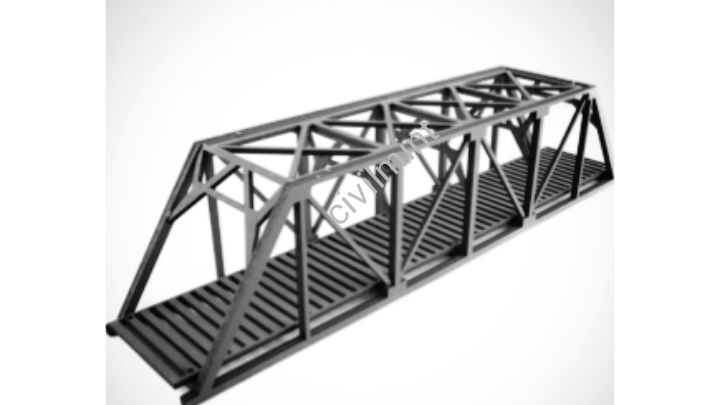

5. Truss Girder Bridge:

Truss girder bridges feature a framework of interconnected triangles that provide excellent strength and stiffness. This design is particularly effective for long spans and heavy loads. Truss girder bridges can have various configurations, such as Pratt, Warren, and Howe trusses.

6. Plate Arch Girder Bridge:

Plate arch girder bridges combine the features of arches and girders by using horizontal arches made of steel plates. These arches are supported by vertical girders, creating a distinctive appearance while efficiently carrying the load.

7. Reinforced Concrete Girder Bridge:

Reinforced concrete girder bridges use reinforced concrete girders to support the bridge deck. These bridges offer durability and can be designed to accommodate different loads and span lengths. They are commonly used for urban and suburban settings.

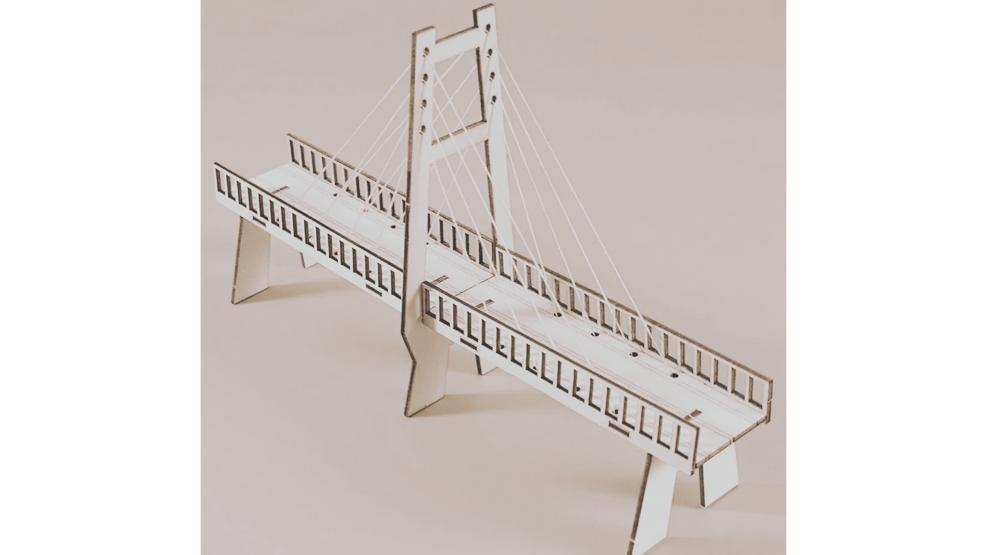

8. Cable-Stayed Girder Bridge:

Cable-stayed girder bridges employ cables that are attached to tall towers and anchored to the bridge deck. The cables provide support and help distribute the load to the towers. This design allows for longer spans and is often used for modern, aesthetically pleasing bridges.

Components Of Girder Bridge

a) Superstructure Components:

Deck: The deck, serving as the surface for roadway or walkway, commonly takes the form of a poured reinforced concrete slab. However, it may also encompass steel grid or wooden plank variations. Inclusive of road lanes, medians, sidewalks, parapets, railings, and drainage elements, the deck harmonizes various functional aspects.

Supporting Structure: This encompasses the steel or concrete system that underpins the deck. It includes girders, diaphragms or cross-braces, and, when applicable, truss or arch systems. In the case of a girder bridge, it pertains exclusively to girders and their bracing system. Girders assume the primary load-bearing role, with the bracing system ensuring their unified function and safeguarding against toppling.

Bearing Pads: These components facilitate relative movement between the superstructure and substructure. Addressing natural material expansion and contraction due to temperature variations, bearing pads mitigate structural stress. By allowing one end of a span to move longitudinally while anchoring the other, these pads enhance the bridge’s longevity.

b) Substructure Components:

Abutment: The abutment, acting as a foundation, transfers the bridge structure’s weight to solid ground, ensuring stability. A counterpart to the abutment, the pier serves as an intermediate support.

Cap: Supporting the bearing pads, the cap’s presence depends on the support structure type. While wall piers and stub abutments lack a cap, multi-column, hammerhead, or pile-bent piers incorporate one.

Stem or Stub: Serving as the foundation’s core, the stem or stub facilitates the transfer of load from the superstructure through the cap and down to the footer.

Footer: Responsible for transferring loads into the ground, the footer operates through two primary systems: a spread footer, a basic concrete slab atop bedrock; and a piling cap, employing steel piles to reach deep-seated, stable bedrock. An alternate system employs caissons or steel-reinforced concrete “pillars” beneath the stem.

You might also like: Difference between beam and girder

Conclusion

A Girder Bridge is purpose-built to support varying dynamic loads over time, such as wind forces, water current pressures, seismic activity resulting from earthquakes, and the rolling loads from moving vehicles.

This type of bridge design is meticulously engineered to withstand compressive, tensile, and bending stresses. Typically found in high-traffic areas requiring longer spans, Girder Bridges offer robust solutions for transportation needs.