Table of Contents

What is Immersed Tunnel?

Immersed tunnel is underwater tunnel which consists of various segments. These segments are created at different location in the sea water. These underwater segments joined together to construct a tunnel. Immersed tunnel is also known as immersed tube or immersed tube tunnel.

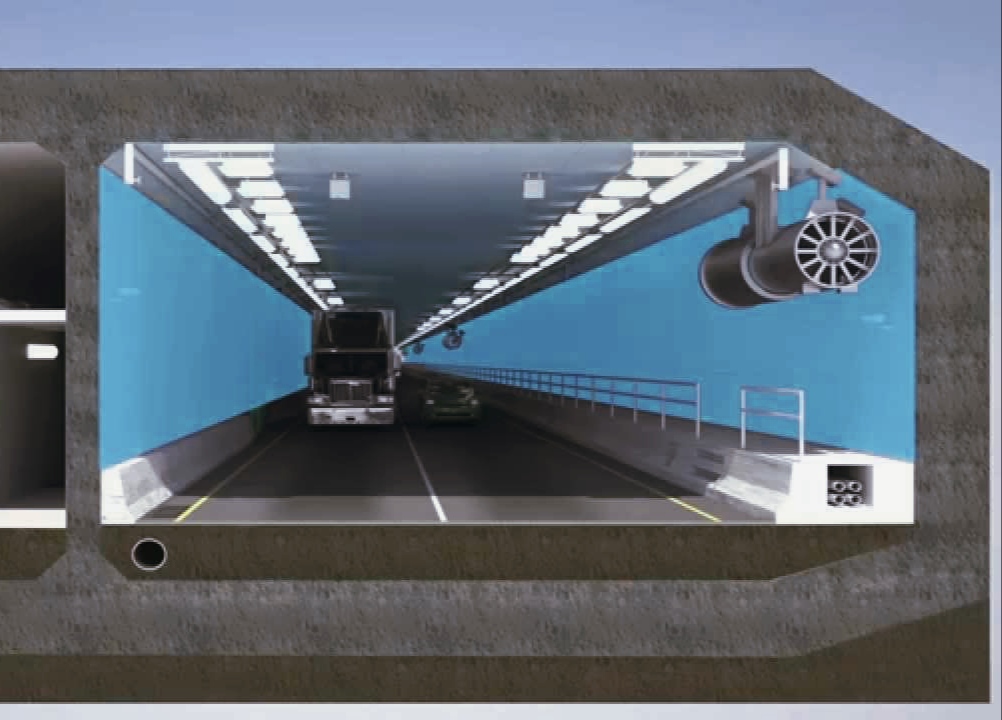

See the below image of immersed tube tunnel.

Immersed tunnels are buil across road, river, rail crossings, canals and ports.

Underwater tubes are often used in combination with other tunnel shapes at their ends. An excavated tunnel usually required to continue a tunnel from the water’s edge to a surface entrance.

Working Concept and Construction Details

Immersed tunnel is made by various prefabricated components. These components joined together to construct immersed tube.

Each components have different manufacturing process that is why it is very difficult to manufacture these component on the construction site.

These components then sealed at the ends with bulkheads so they can float. Corresponding sections of the tunnel route were prepared, with a trench at the bottom of the channel dredged and leveled with good tolerances to support the elements.

The next step is to put the parts in place, each part being pulled to its final position, which in most cases requires assistance to keep afloat. Once in place, additional weight is used to push the element into final position, which is an important step in ensuring each part is properly aligned. After laying, the joint between the new element and the tunnel is emptied and then sealed, which continues sequentially along the tunnel.

The groove is then backfilled and any necessary protections, such as riprap, are added on top. The ground next to each end of the tunnel will usually be reinforced, to allow the tunnel boring machine to drill final connections to the shore ports. After these steps, the tunnel is completed and the interior can be installed. Pipe segments

Immersed tunnel can be constructed in two ways. In the United States, the preferred method is to build steel or cast iron pipes and then encase them in concrete. This allows conventional shipbuilding techniques to be used and segments to be launched in the dock after assembly. In Europe and Asia, the construction of reinforced concrete tubular boxes is the norm. Portions are poured into a basin and then immersed to allow for their evacuation.

Key Benefits of Immersed Tube

- Construction speed is very fast, because prefabricated components are used to construct.

- Minimal disruption to natural and artificial water bodies.

- It is seismic resistant.

- Construction work is safe.

Some Drawbacks

- Underwater tunnels are often partially exposed in sea water.

- Joints must be carefully sealed due to direct contact with water.

- The segmental approach requires careful design of longitudinal actions and connections that must transmit forces laterally.

- Environmental impacts of pipes and subsea dams on existing watercourses.