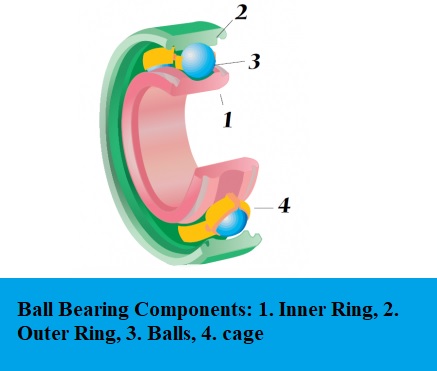

There are 5 main components of the standard ball bearing as follows:

- Inner Ring.

- Outer Ring.

- Balls.

- Cage.

- Lubrication

I have described these 5 components in brief.

Table of Contents

1. Inner Ring:

It is the smaller of the two bearing rings. There is a groove on the external diameter to make a pathway for the balls.

The external diameter path is finished to a very tight tolerance and is honed to an extremely smooth. The inner ring is mounted on the shaft and this part is the rotating element.

2. Outer Ring:

The Outer Ring is the bigger of the two bearing rings. On the external ring, there is a groove on its inside breadth to frame a pathway for the balls. The external ring surface likewise has a similarly high accuracy finish of the inward ring. The external ring is typically held stationary.

3. Balls:

Balls of a bearing are the moving components that differentiate internal ring and external ring and allow the bearing to rotate with minimal friction.

The radius of the ball is made somewhat more modest than the grooved ball track on the inward and external rings. Ball measurements are controlled to extremely high exactness. Ball roundness, surface completion, and size varieties are significant credits. These attributes are controlled to a miniature inch level.

4. Cage:

The purpose of the cage in a ball bearing is to isolate the balls, maintain a constant spacing between the inner and outer rings, accurately guide the balls in the path during rotation, and prevent the balls of bearing from falling out.

5. Lubrication:

The lubricant is an integrated part of a bearing’s standard components. Lubrication is added to decrease friction losses in bearing between inward and external rings.