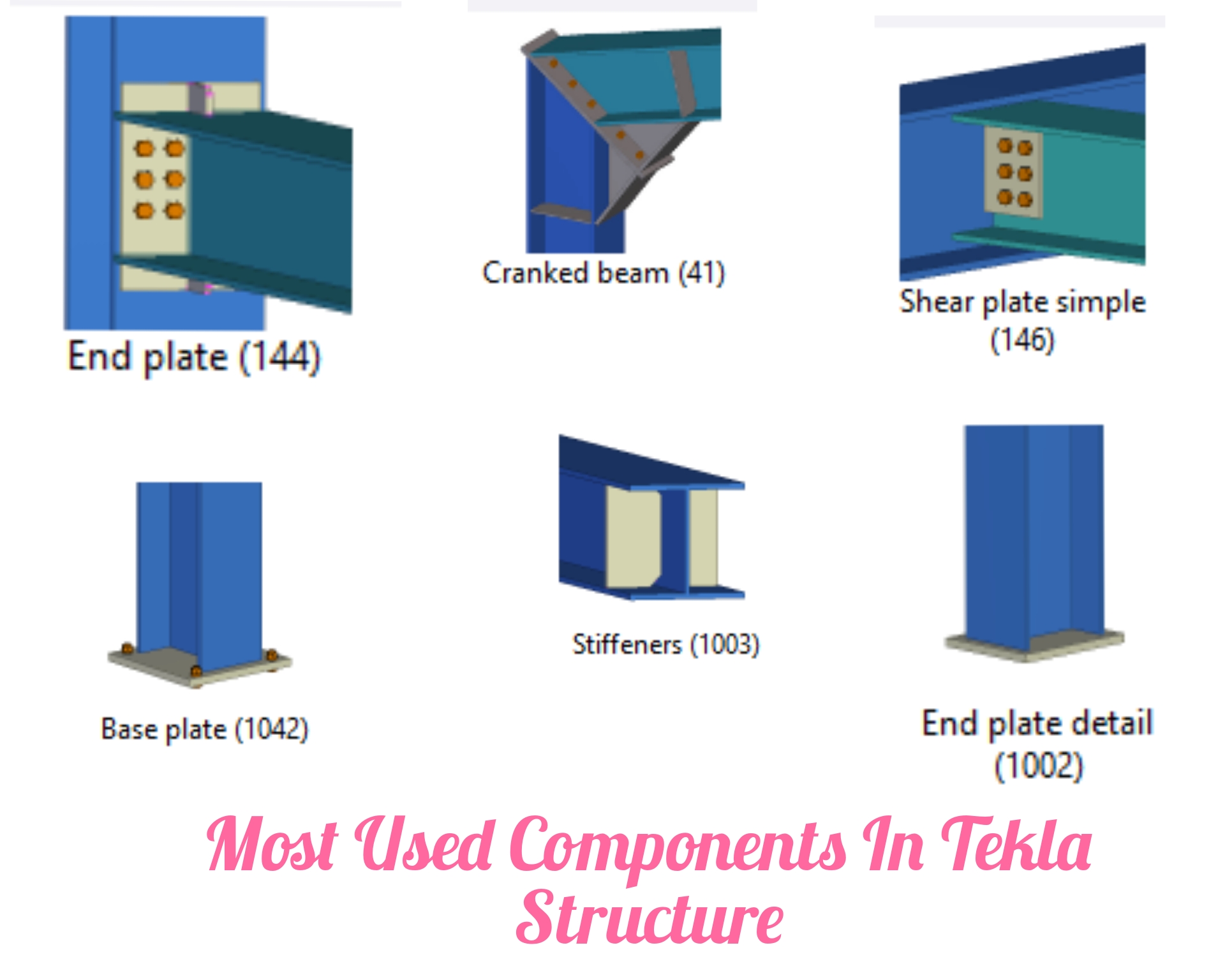

Here are the most used components in Tekla structure.

Table of Contents

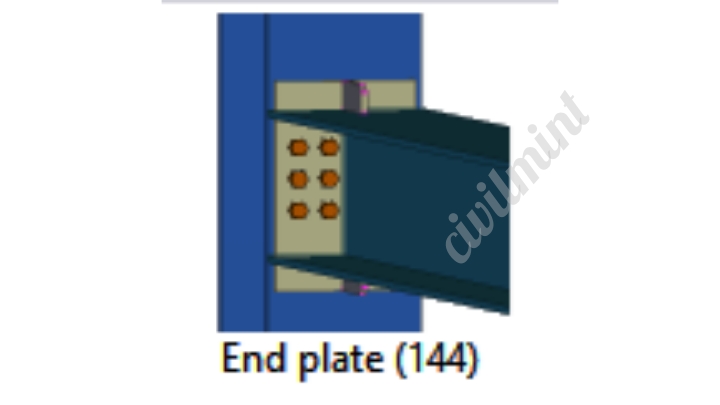

1. End Plate (144)

End Plate (144) is one of the most used component to creat a model in tekla structure.

The End Plate (144) enables the connection of two beams or a beam to a column through a bolted end plate. The secondary part can be sloped, leveled, squared, or skewed, allowing for various end plate connections like full depth or partial depth connections. Additionally, users can incorporate haunches, shims, stiffeners, and notches as required to enhance the overall design.

2. Cranked Beam (41)

If you are a professional designer then you would know the importance of the Cranked Beam (41) component.

The cranked beam (41) is a structural component that serves to connect two beam ends. The angles of the beam ends are carefully aligned to create an average angle, allowing for the seamless integration of the elements. Additionally, this component allows the option to incorporate a plate between the elements and use haunches for added support. Its primary application lies in creating precise miter cuts. The members are automatically welded, and the user can specify the desired weld type and size. This versatile component is suitable for various profiles.

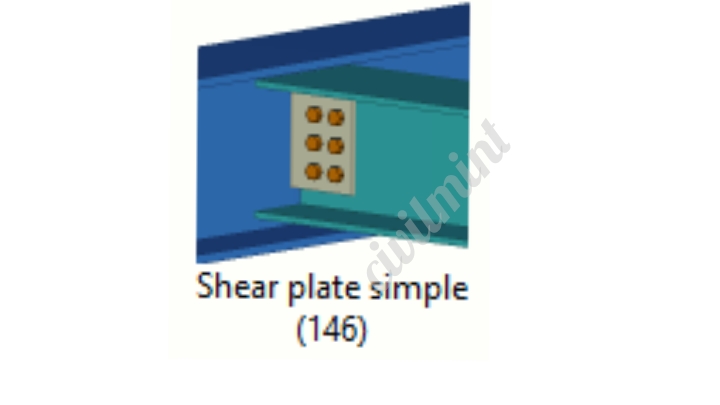

3. Shear Plate Simple (146)

The shear plate simple (146) is a crucial component utilized for connecting two beams or a beam to a column. It consists of a single or double square shear tab that is welded to the main part and bolted to the secondary beam web. Additionally, engineers have the flexibility to incorporate a stiffener plate on the opposite side of the main part, as well as haunch plates and seat angles, to further enhance its structural capabilities.

4. Base Plate (1042)

The base plate (1042) is an essential component used in constructing a base with anchors. It facilitates the creation of an end plate that is welded to the column and connected to the base through anchors. Additionally, it enables the inclusion of a cast plate, which serves as a means to attach the anchors and grout. This feature is valuable in accurately modeling columns on concrete structures.

5. Joining Plate (14)

This element serves as a practical solution for connecting two beam ends. It involves the creation of two end plates, which are welded to the beams and then joined together using bolts. Additionally, spacing between the plates can be adjusted by incorporating shims, and stiffeners may also be added for enhanced support.

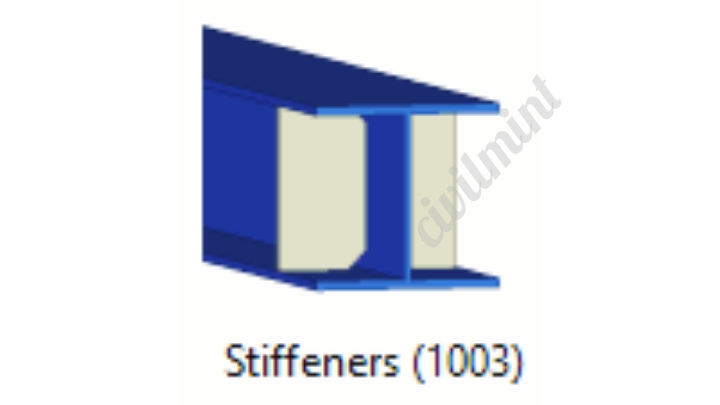

6.Stiffeners (1003)

This component provides automated functionality for integrating stiffeners into your model. It allows you to customize the thickness, width, and height tolerances between the flanges of the I beam, streamlining the process of adding stiffeners to your design.

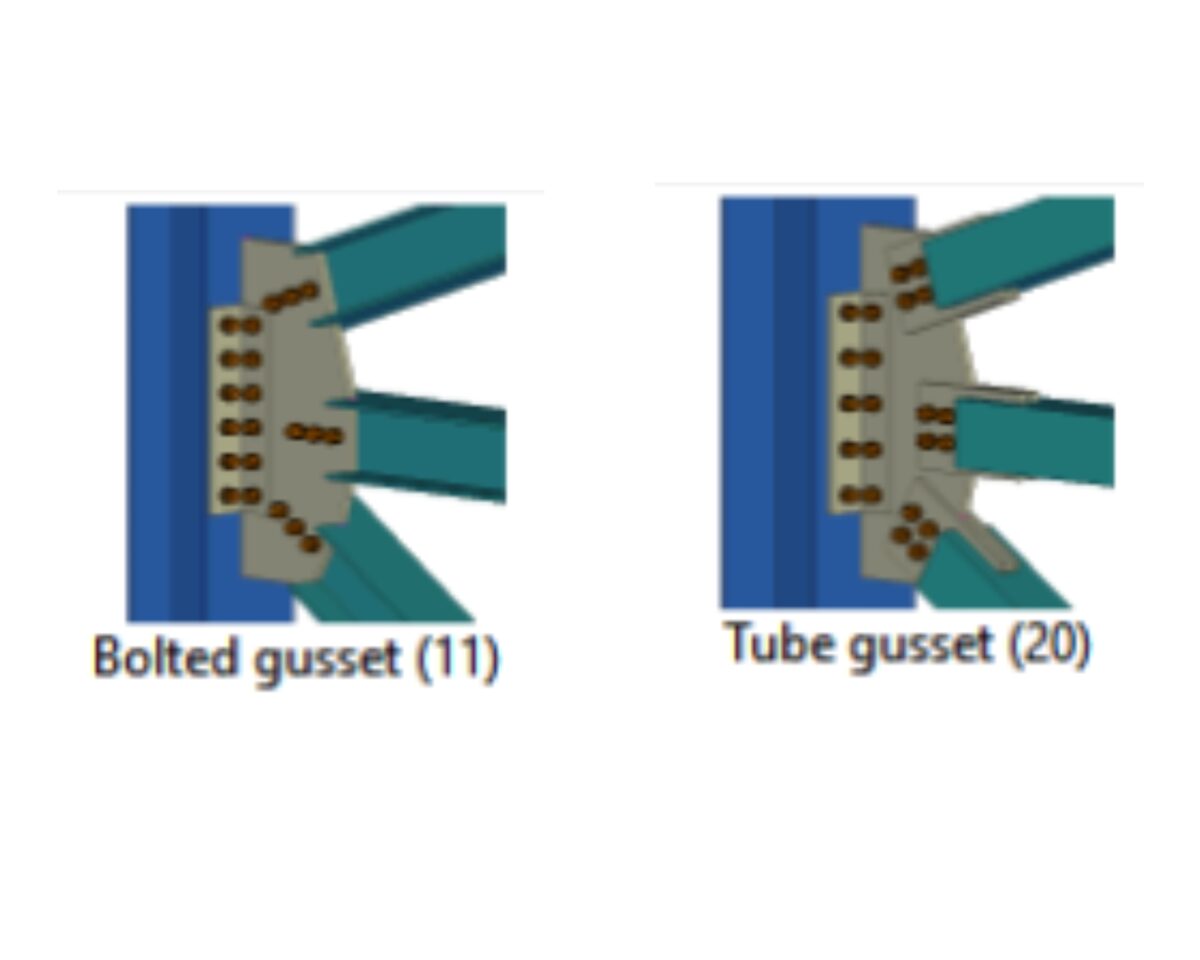

7. Bolted Gusset (11) And Tube Gusset (20)

The bolted gusset (11) and tube gusset (20) serve the purpose of connecting the bracing profile to a column or beam with a gusset plate. Depending on whether a hollow/tube profile or an open section is used as bracing, one of these components is chosen accordingly. The gusset plate can be either bolted or welded to both the main part and the bracing. Furthermore, additional clip angles can be incorporated, and end plates can be used to seal the hollow sections.

8. End Plate Assembly (1002)

This feature enables the quick creation of an end plate that can be welded to the beam or column end. It is user-friendly and can significantly improve productivity.

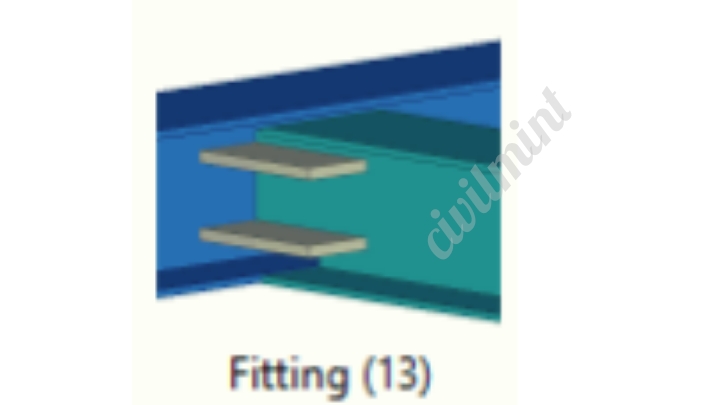

9. Beam Fitting Connector (13)

This practical component facilitates seamless beam connection through welds, eliminating the need for creating additional views or using line cuts and part cuts.

10. Haunch (40)

The Haunch component serves the purpose of connecting a beam to a column by utilizing a welded plate or profile haunch, along with a bolted end plate. This type of connection ensures a robust and stable joint between the beam and the column. In addition to the primary haunch and end plate, users have the option to include additional components like a top plate, stiffeners, cap plate, web plate, and more. This flexibility allows engineers to tailor the connection to specific project requirements, ensuring structural integrity and safety.

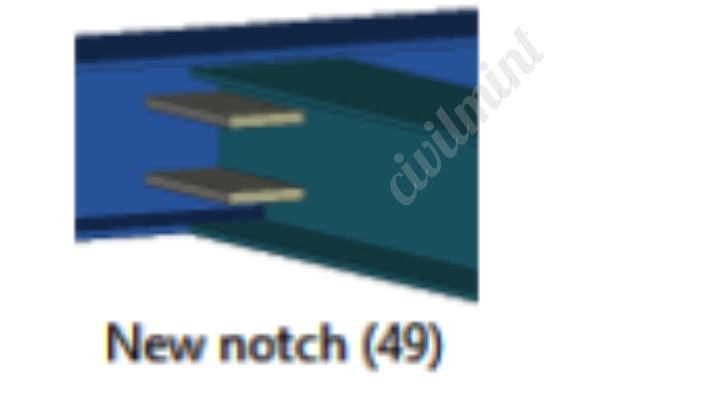

11. New Notch (49)

The New Notch component facilitates the welding of two beams together, providing a reliable and efficient method of connecting beams in various structural applications. Users can specify the notch configuration for the beam ends, allowing for precise and customized connections. Additionally, horizontal stiffeners can be added to enhance the overall load-carrying capacity and resistance against bending moments. This component proves especially useful in scenarios where continuous or moment-resisting beams are necessary for the structural design.

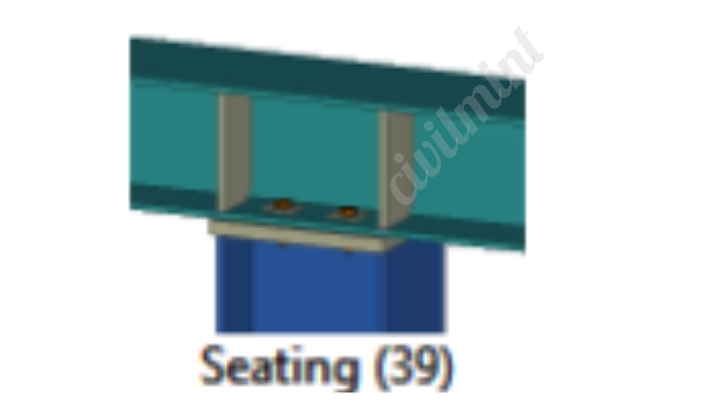

12. Seating (39)

The Seating component offers a connection solution similar to the End Plate (144) for columns, enabling the creation of a welded end plate on the column head. This end plate is then bolted securely to the lower flange of the secondary beam. To further reinforce the joint and enhance load distribution, engineers can incorporate stiffeners and washer plates as needed. The Seating component ensures a strong and reliable connection between the column and the secondary beam, ensuring stability and load transfer efficiency.

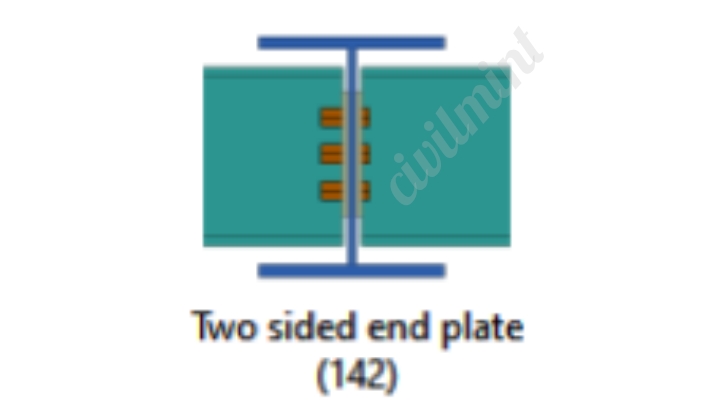

13. Two-Sided Plate (142)

The Two-Sided Plate component is employed to connect two beams to either a beam or a column using the same bolt group throughout all three parts. This type of connection offers simplicity during installation, as it allows for a consistent bolt group, reducing complexity and easing on-site assembly. Engineers can confidently utilize this component to establish secure connections between beams and columns, enabling the seamless transfer of loads and ensuring the structural integrity of the entire system.

14. Stanchion Weld (85)

The Stanchion Weld component is designed to precisely fit and weld a profile to a flat surface of another part. It closely resembles the native Tekla command ‘Fit Part End’, but without the requirement of creating a perpendicular view to the element. This feature streamlines the connection process, offering a convenient and time-saving method for joining different elements together. The Stanchion Weld component proves particularly valuable when connecting structural members in complex assemblies, enhancing overall efficiency and accuracy in the design and construction process.

You can also read my article on Stiffener Plate In Steel Structure.

Conclusion

These are the most commonly used components in Tekla structure software. Structural modelers and design engineers must know these components in order to get their work done at a faster pace.