Table of Contents

Introduction of Jackscrew

Jackscrew is also known as Screw Jack. Jackscrew is one of the most common types of linear motion actuators used to lift or move loads. It can also be used in applications that require linear motion or need to be driven or towed along a linear axis. Lead, ball, and socket head screws are simple mechanical actuators.

A jack that acts to rotate a spindle is called a spindle or spindle jack. It is often used to lift medium to heavy weights. B. Vehicle used. Elevator for raising and lowering aircraft. As a comfortable heavy load such as the foundation of a house.

The most popular jack screw type is the traditional hand type, where force is applied to a lever to lift the screw from the base of the unit to raise or lower the load. AC or DC motors are well-known methods of driving spindles.

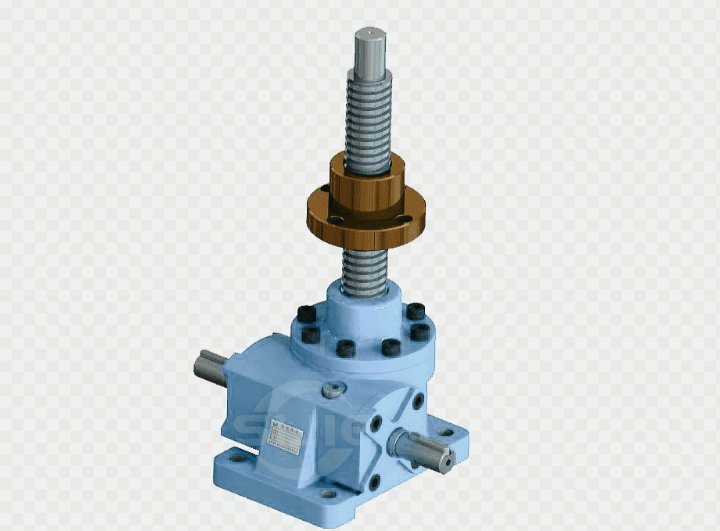

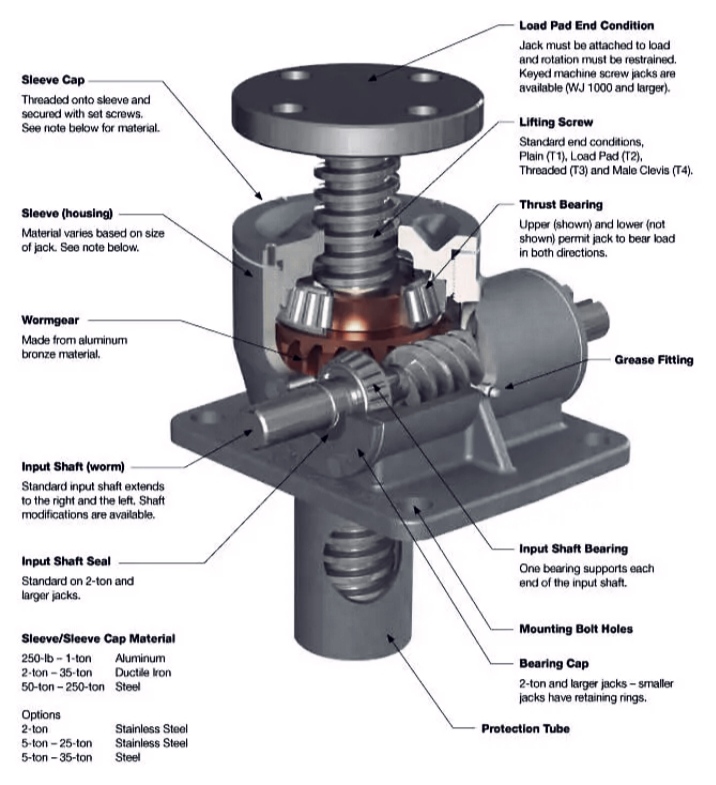

Construction Details of Jackscrew

The jack consists of a heavy-duty vertical bolt mounted on top that screws into holes in a heavy-duty frame with a wide base resting on the ground.

Screw jacks are indispensable for automatic machines. Safety and regulatory concerns are driving the automation of heavy load handling and lifting, especially in areas with labor, health and safety laws.

How Does Jackscrew Work

A screw jack is a gear assembly (either worm gear or bevel gear) and transmission product (roller screw, ball screw, or lead screw) that uses a motor to convert rotary motion into linear motion. They can push, pull, pull, latch, unlatch, tilt, rotate, roll, slide, lift and lower loads ranging from kilos to thousands of tons.

Screw jacks are indispensable for automatic machines. Safety and legal concerns drive automation of heavy load handling and lifting, especially in areas with labor, health and safety laws.

Diffrent Types of Jackscrews

- Rotating Screw Jack

- Translating Screw Jack System

Advantages of Jackscrew

One advantage of jackscrews over other types of jackscrews is that they are self-locking. This means that no matter how hard the screw rotates, it will stay where it stopped and never come back. This improves the safety of hydraulic cylinders, such as the ability to roll back under load if force on the hydraulic actuator is accidentally released.

Some Drawbacks of Jackscrew

- There is a limit to the lifting capacity of screw jacks.

- As the friction of the thread increases, the load increases.

- A thin thread increases the usability of the screw, but also reduces the working speed.

Applications/Uses of Jackscrew

A large sliding contact area between the threads means that the lifting screw has high friction and is less efficient as a power transmission linkage, around 30% to 50%. As such, it is less commonly used for high-power continuous transmissions, but more commonly used for intermittent positioning applications.

Heavy-duty applications such as the jackscrew use square or buttress threads for the lowest friction and wear.