The Bitumen Extraction Test is a commonly used method to determine the amount of bitumen present in asphaltic pavement through cold solvent extraction.

The percentage of bitumen in the pavement plays a crucial role in determining the durability, compatibility, and resistance to defects such as bleeding, raveling, and aging of the flexible pavement.

Thus, it is essential to accurately determine the bitumen content to ensure the quality and longevity of the pavement.

Table of Contents

Objective

The objective of this test is to ascertain the amount of binder content, specifically bitumen, present in the asphalt mixture through the utilization of the cold solvent extraction technique.

Code Of Standards

- IRC: SP 11 –1988 (Appendix – 5)

- ASTM D 2172

Equipments For Test

To conduct certain scientific experiments, the following equipment may be required:

- A centrifuge.

- A balance with a capacity of 500 grams and a sensitivity of 0.01 grams.

- An oven that is thermostatically controlled and can handle temperatures up to 2500 degrees Celsius.

- A beaker for collecting the extracted material.

Test Procedure

- Place exactly 500 grams of the representative sample in the bowl of the extraction apparatus (W1).

- Add benzene to the sample until it is completely submerged.

- Dry and weigh the filter paper, and place it over the bowl of the extraction apparatus containing the sample (B).

- Clamp the cover of the bowl tightly.

- Place a beaker under the drainpipe to collect the extract.

- Allow sufficient time (not more than an hour) for the solvent to disintegrate the sample before running the centrifuge.

- Run the centrifuge slowly and gradually increase the speed to a maximum of 3600 rpm.

- Maintain the same speed until the solvent ceases to flow from the drainpipe.

- Run the centrifuge until the bitumen and benzene are drained out completely.

- Stop the machine, remove the cover, and add 200ml of benzene to the material in the extraction bowl.

- Repeat the same process not less than three times until the extraction is clear and not darker than a light straw color.

- Collect the material from the bowl of the extraction machine along with the filter paper and dry it to constant weight in the oven at a temperature of 1050 C to 1100 C.

- Cool the material to room temperature and weigh it (W2) and the filter paper (D) separately to an accuracy of 0.01grams.

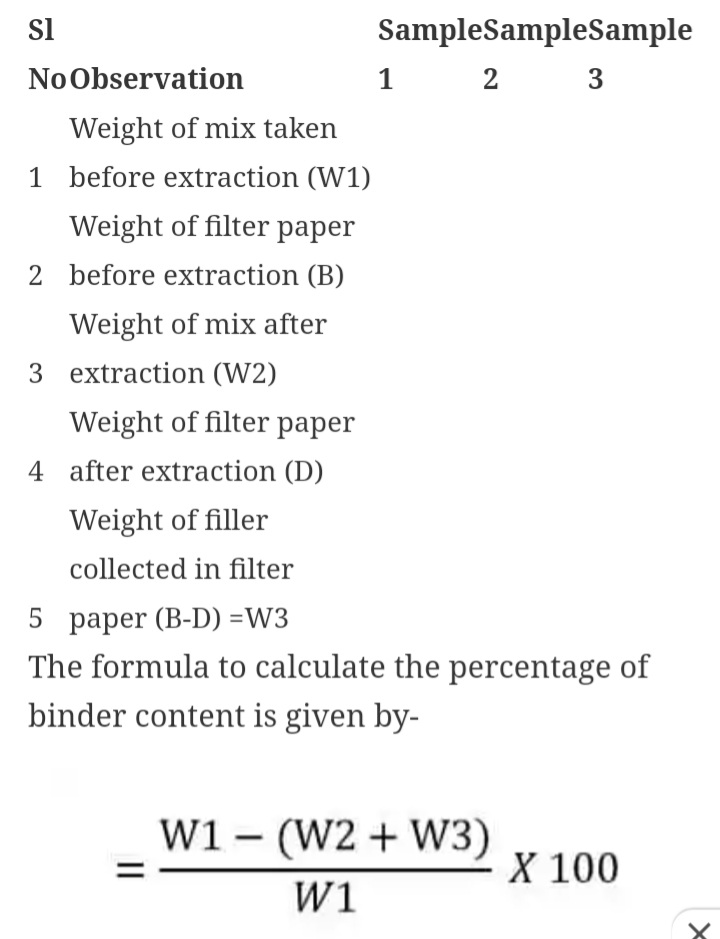

Bitumen Extraction Test Calculation

Bitumen Extraction Test Result