Here is the most common test of brick.

- Water Absorption Test of Bricks

- Efflorescence Test of Brick

- Compressive Test of Brick

- Hardness Test of Brick

- Shape and Size Test of Brick

- Soundness Test of Brick

Let us discuss these brick tests in detail.

Table of Contents

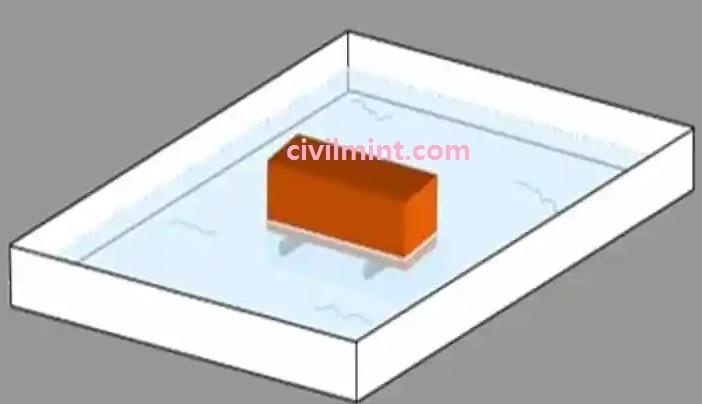

1. Water Absorption Test of Bricks

Water absorption test can be performed in two ways:

- 24-hour immersion cold water test

- 5-hour boiling water test

24-hour Immersion Cold Water Brick Test

- The dry specimen is put in an oven maintained at a temperature of 105 to 115o C and kept there until it attains substantially constant mass.

- After the material was cooled, the weight of the specimen was recorded. Let this weight be W1.

- To assess dry samples, place them in a container of water at 27ºC for 24 hours.

- Take the specimen out of the water and wipe it off with a dry cloth.

- After weighing the specimen, it’s done quickly by 3 minutes. Let this weight be W2.

- Water absorption after 24 hours of immersion in cold water is given by = (W2 – W1) x 100 / W1

5-hour Boiling Water Brick Test

- First, the brick sample is dried in an oven at 105o C to 115o C temperature till it archives constant mass.

- Then, cool this brick sample at normal room temperature and record the weight of the brick sample. This will be W1.

- After that, the brick is kept immersed continuously immersed in boiling water for 5 hours.

- The brick sample immersed in water is allowed to cool at 27 ± 2o C.

- The brick sample is taken out and wiped with a damp cloth.

- Complete the weighing of the specimen in three minutes. This will be W3.

- Water absorption after 5 hours of immersion in boiling water is given by = (W3 – W1) x 100 / W1

2. Efflorescence Test

Presence of salt in brick cause efflorescence. We can calculate the efflorescence of bricks by the efflorescence test.

Put one end of the bricks in a 25 mm depth of water. The diameter of the dish should be at least 150 mm and a depth of 30 mm. The dish is made of porcelain, glass, or glazed stone. Experiments are performed in a well-ventilated room at a temperature of 20-30°C until all the water in the cup has been absorbed or evaporated by the sample. After the sample has dried, add an equal amount of water to the cup and allow the sample absorbed by the specimen for efflorescence after the second evaporation.

Efflorescence in brick is represented by nil, slight, moderate, heavy, or serious as defined below:

Nil:

When salt precipitation is not detectable, it is said to be zero.

Slight:

If efflorescence is not more than 10% of the surface area of bricks, it is said to be slight.

Moderate:

When the deposit of efflorescence is heavier than slight and does not cover more than 50 percent of the exposed area of the brick surface. There should not be powder or flake on the brick exposed surfaces. There should be no dust or flakes on the exposed surface of the brick.

Heavy:

If the efflorescence area is more than 50 percent, it is said to be efflorescence salts are heavy. There should be no dust or flakes on the exposed brick surface.

Serious:

Efflorescence is considered severe if the exposed surface of the brick has powder or flake salts.

3. Compressive Test on Brick

Good quality brunt clay brick is selected for the compressive strength test brick. Both faces (top & bottom) of bricks are ground to give a smooth and even surface for the test. After that brick is put in water at room temperature. Clean the upper deck of bricks, fill with cement mortar (1 part cement and 1 part clean coarse sand not more than 3 mm), soak in a wet jute bag for one day, then soak in clean water for 1 hour. 3 days. Take out the brick sample and remove excess water from the surface. Place the sample bricks between two sheets of plywood, each 3 mm thick, with the flat side horizontal and the grouted side facing up. Carefully place the sample bricks between the plywood sheets in the center of the compression tester. The gage of the machine is clamped and tightened, and an axial load of 140 kg/cm2 per minute is applied to failure at a uniform rate. The maximum load on the pointer indicator is indicated while the brick sample is being destroyed.

Compressive strength = maximum load at failure/ Base are of Brick.

Result

Average compressive strength of the brick sample =………….. N/mm2

4. Hardness Test on Brick

The hardness of a brick can be judged by scratches on the brick using fingernails. Scratch the pattern on the brick, and if there are no scratches on the surface of the brick, it is judged to be of sufficient hardness.

5. Shape and Size Brick Test

The shape of the brick must be a true rectangle and have standard dimensions according to the relevant set of rules.

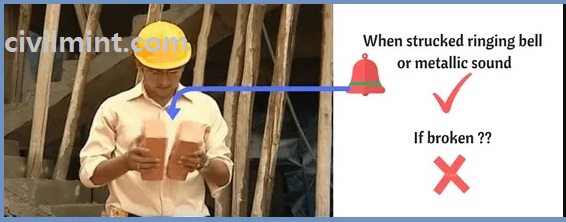

6. Soundness Test of Brick

The soundness test of bricks is done by hitting two bricks against each other. You should hear a brick-breaking sound. You can check this by dropping a brick. A high-quality brick should not break when dropped on a hard floor from a height of about 1 m.

This test is used to check the quality of brick on construction sites.

You May Also Like:

- What is Civil Engineering?

- Bidding Process to Select Contractor for Construction Projects

- How to Repair Potholes on Bituminous Roads

- Lap length of reinforcement bars/Lapping Length of Steel Bars

- Stress-Strain Curve for Mild Steel Explained

- Top 25 Auto Cad Command for Draftsman and Engineers

- Slump Test Step By Step Procedure And Types Of The Slump

- What are Admixtures? And its Types

- Fick’s Law Of Diffusion

- Two Stroke Vs Four Stroke Engine