Rockwell hardness test is used to calculate the hardness of a material. It can calculate the hardness of various materials such as aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This test provides you with a direct reading of the hardness of the material in just a few seconds.

The hardness of a material is characterized by its protection from indentation. Rockwell hardness test measures the permanent depth of indentation on metal by applying a fixed load using an indenter. If the indentation value is low, the material will be harder.

Stanley Rockwell and Hugh Rockwell invented the Rockwell hardness test together. Both of them were from Connecticut, the United States. This whole test relies on the differential depth hardness measurement process. Based on this differential depth measurement, they both also discovered the Rockwell hardness tester which measures the accurate hardness of the material.

Indenter used in the Rockwell Hardness Test

In this test carbide balls or diamonds which is in the shape of a square pyramid are used. In some rare cases, the steel ball is also used as an indenter. Other types of intenders can be used as per requirement but most of the times carbide balls or diamonds are used as the most common indenters.

Rockwell Hardness Test Procedure

We will discuss all the steps one by one to make it easy for you.

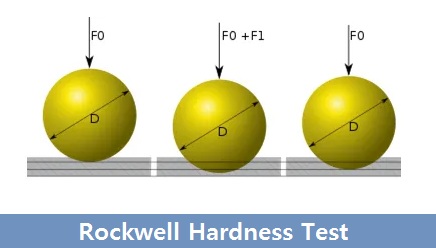

Step 1: In the very first step you have to apply a minor load (f0) on the indenter. The value of this minor load is generally 10 kgf. This load is also known as zero load. This load assists to establish the reference position from which further measurements are to be calculated.

Step 2: Now, a major load (F1) is applied in addition to this minor load. Because of the applied load, the indenter penetrates inside the material.

Step 3: After 10-15 times, the major load is removed and the minor load is still applied. After 15 seconds of removing the major load, a measurement is taken. The depth of the penetration of the indenter from the reference line gives the hardness of the material.

There is also the Rockwell hardness tester machine which gives you correct reading with almost no errors. The machine consists of the scale which gives the hardness of the material. In most of the applications, this machine is used.

Nowadays Rockwell hardness tester is used to avoid manual calculation. It gives you the correct reading without any errors.

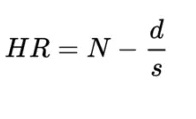

The hardness of the material is calculated from the formula given below:

Where,

- d= depth of the penetration of the indenter from the reference line or the zero-position line.

- N and s are nothing but the scale factors which depend on the type of the Rockwell scale.

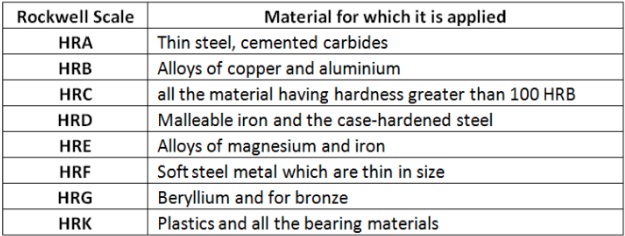

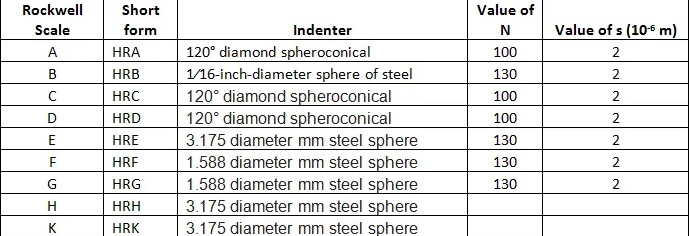

Are you thinking about the types of the Rockwell hardness test? It is weird to know that there are more than 30 different Rockwell hardness scales are there. And each of these scales has different values of the N & s. HRA, HRB, HRC, HRD, HRE, HRF, etc. are the various types of the Rockwell hardness scale.

HRB and HRC are the most popular and widely used Rockwell hardness scale. Other types of hardness scales can be used based on the application.

Let’s take a look at some of the Rockwell hardness scales and their N, s values as well as the type of the indenter used in those scales.

We should see for which material which Rockwell hardness scale is utilized.