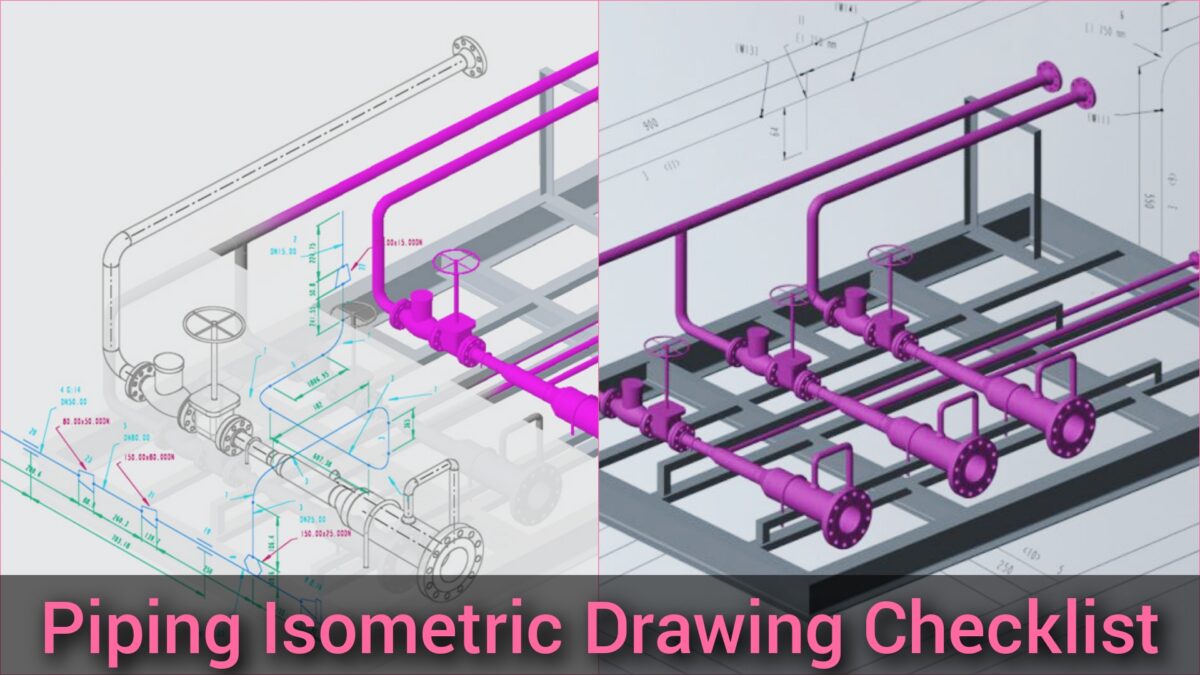

The piping isometric drawing checklist is an essential checklist used by designers, engineers, and inspectors to guarantee the precision, comprehensiveness, and compliance of piping isometric drawings.

Its purpose is to meticulously review and validate multiple elements of the drawing, including pipe routing, labeling, dimensions, and adherence to industry standards and codes.

This checklist plays a crucial role in confirming the accurate depiction of the piping system’s layout, dimensions, and connections.

By adhering to the checklist, professionals actively verify that the piping isometric drawing aligns with the required specifications, thereby facilitating the efficient construction and installation of the piping system.

See the below table of piping isometric drawing checklist.

| S.NO | CHECK POINTS | P | R | A | REMARKS |

| 1 | A: -IS THE ISOMETRIC LISTED IN ISOMETRIC INDEX. B: -HAS A COPY OF ISOMETRICS BEEN TAKEN AND MARKED AS CHECK PRINT? | ||||

| 2 | HAS THE ISOMETRIC BEEN PREPARED AND CHECKED AGAINST LATEST REVISION OF THE FOLLOWING RELEVANT DOCUMENTS. P&ID LINE LIST GAD OR 3D MODEL (PDMS, E3D, SP3D), EQUIPMENT LAYOUT. PMS VENDOR DRAWING UPDATED | ||||

| 3 | ARE THE FOLLOWING MARKED /TAKEN CARE OF? A: -COMPLETE LINE INFORMATION, INCLUDING SIZE, LINE NO, SPEC, INSULATION TYPE ETC. B: -FLOW DIRECTION ARROW C: -ALL CONTINUATION/CONNECTED REFRENCE. DIMENSIONS: – E: -TYPE OF BRANCH CONNECTION/BRANCH REINFORCEMENTPAD DIMENSIONS (SPECIAL CASE) F: -SLOPE AND WORKING POINT ELEVATION IN CASE OF SLOPING LINE. G: -LOW POINT DRAIN AND HIGH POINT VENTS. SPECIALITIES (THOSE FOR VALVE). I: -SPECIAL PIPING ITEM TAGGED J: -SPECIAL NOTES FROM P&ID AND FROM ANY OTHER RELEVANT DOCUMENTS. K: -REVISION NUMBER AND DATE L: -HOLD IN ABSENCE OF REQUIRED INFORMATION. M: -STRESS ANALYSIS REQUIREMENT. N: -STRESS RELIEVING REQUIREMENT. O: -INLINE AND ON-LINE REQUIREMNT. P: -CROSS SECTIONSHOWING ORIFICE FLANGE TAPPING ORIENTAION. Q: -BREAK-UP FLANGE OPENING, CUTOUT, ELEVATION OF PLATEFROM. S: -EXACT LOCATION OF SPEC BREAK (FLANGE FACE OF LINE WELD. T: -COTROL VALVE DIMENSIONS AS PER INSTRURMENT DRAWING/LIST/STANDARDS. | ||||

| 4. | IS THE FOLLOWING STRUCTURAL INFORMATION AVILLABLE? GRID AND COORDINATES OF STRUCTURAL MEMBERS IF USED FOR SUPPORTING PURPOSE OR FOR LOCATING PURPOSE | ||||

| 5 | IS THE FOLLOWING EQUIPMENTS INFORMATION AVILLABLE. A: -NOZZLE NUMBER, INCASE IT IS OUT OF, RATING AND FACING. B: -EQUIPMENTS NUMBER AND ITS CENTERE -LINE CO-ORDINATES REFRENCE. ORIENTAION AND ELEVATION OF THE NOZZLE. | ||||

| 6 | IS THE FOLLOWING SUPPORT INFORMATION AVILLABLE? A: -FOR CRITICAL LINES, SUPPORTING INLINE WITH THE RECOMMEDATION OF STRESS ENGINEER (AS MARKED IN STRESS ISOMETRIC) e.g., EXTRA LENGTH OF SHOE, REMOVAL, OF HOT INSULATION LOCALLY, GAP IN SUPPORTS, COLD PULL ETC. B: – FOR NON-CRITICAL LINES, SUPPORTING AS SUGGESTED BY STRESS /SUPPORT ENGINEER/DESIGNER. C: – IN CASE OF NON-STANDARD SUPPORTS, THE SUPPORT NUMBER MARKED AT ALL LOCATION IN PROPER WAY. D: – IN CASE OF NON-STANDARD SUPPORTS, SKETCH DRAWN ON ISOMETRIC ITSELF (IF A SEPARATE SKETCH HAS BEEN ISSUED, HAS A CROSS REFRENCED BEEEN MARKED. E: – IN CASE OF A SUPPORT FROM VESSEL CLIP, CONFORMLY BETWEEN THE TWO 1.SPRING SUPPORT AND EXPANSION JOINT TAG NUMBER IF APPLICABLE 2RECOMMEDATION OF ANALOG /DIGITAL STUDY REPORT | ||||

| 7 | DOES THIS ISOMETRIC INCLUDE MATERIAL TAKE OFF AS WELL IF YES, HAS MTO BEEN CHECKED (IN CASE 3-D MODEELING, ONLY SAMPLE. MTO CHECK IS REQUIRED FOR ‘HOLD’ MERKED ISOMETRIC MUST BE CHECKED TO ELIMNIATE THE POSSIBLITY OF PROCUREMENT OF MATERIAL AGAINST ITEM MARKED AS ‘HOLD’ | ||||

| 8 | DOES THE ISOMETRIC NEED TO BE ISSUED TO PROCESS /POSD/HMTD/PROCESS LICENSOR/VENDOR/OWNER/IBR FOR THEIR APPROVAL? HAS IT BEEN RECORDED IN ISOMETRIC INDEX. IF YES, HAVE THEIR COMMENTS/APPROVALBEEN SOUGHT,RECEIVED AND ISOMETRIC UPDATED. IN NO, HAS THE ISOMETRIC BEEN WITHHELD FOR CONSTRUCTION IN ABSENCE OF COMMENTS? | ||||

| 9 | AS THERE ANY DISCREPANCY/MISTAKE MADE DURING THE CHECKING. HAS IT BEEN COMMUNICATED WITH CONCERNED PERSON/LEAD ENGINEER. HAS IT BEEN MARKED IN MASTER GAD/UPDATED MODEL. | ||||

| 10 | HAS ORIGNAL BEEN BACK- CHECKED FROM THE CHECK PRINT? WHETHER THE ISOMETRIC CONTAINS ALLM SIGNATURE, REVISION NO. HAS THE ISOMETRIC INDEX BEEN UPDATED? IN REVISED ISOMETRIC REVISION INDEX AND CLOUD OF REVISED PART CHECKED. TITLE BLOCK CHECKED PROPERLY (LINE NO, PROJECT NAME AND NO, AREA, UNIT NO, ETC. |