Table of Contents

What Is Pipe Spool Drawing?

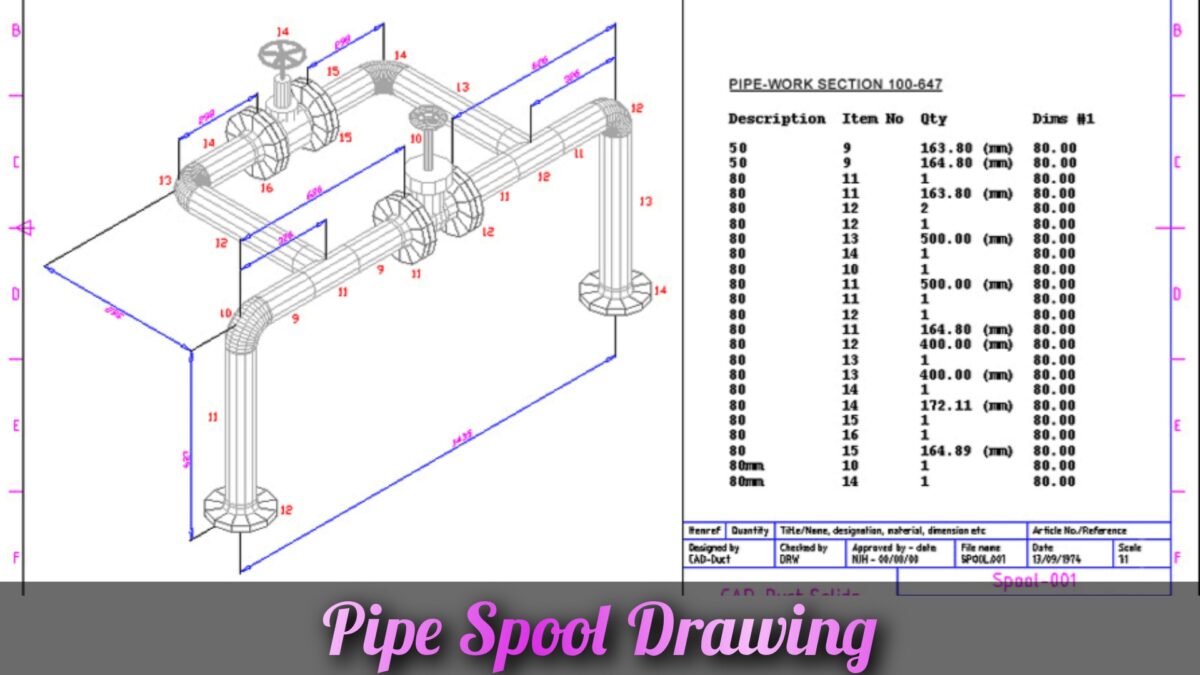

A pipe spool drawing is like a detailed map of a small part of a pipe system. It shows how the pipes, fittings, and other parts are arranged and connected.

These drawings are used to help people build the pipes correctly and make sure everything fits together well. They make the whole process easier and more accurate.

Description

Piping is a complex network used in process and power plant which belongs from samall bore (SB) to large bore pipe upto 48″.

But it is part of the entire piping that goes end-to-end in the plant. Pipe spool is very useful to reduce the construction cost.

Pipe spool depend upon the box in which pipe spool transport.

Various factors are considered for pipe fabrication.

- Type of project.

- Material supplier vendor location.

- Site location from the fabrication shop.

- Required welding facility and resources.

- New project or existing project renovation.

Most importantly, the transportation cost and site construction cost should be calculated while finalizing the spool contactor.

If material supplies from china and project execute in india then fabrication vendor should be near project site to minimize cost of transportation of spool to site.

For very big project fabrication can be performed in site fabricated shop.

Pipe fabricators typically have a productive workshop facility to handle projects of various sizes.

A purpose-built workshop that protects the worker and the work from the elements along with efficient machinery and equipment, and a skilled craft workforce makes shop fabrication the ideal response for most piping projects.

Input For Piping Spool Fabrication Process:-

- Piping isometrics with latest revision from piping design department.

- Welding specification

- Pipe fabrication specification.

- Spool drawing.

- Inspection and testing requirement.

- Applicable code and standards.

Spool process:-

1. Marking

Pipe materials are marked on pipe and verified as per pipe fabrication specifications.

2. Tagging

Pipe materials are tagged using tag and stamp ot paint to ensure pipe heat number.

3. Cutting:

Pipe cutting methods such as saws, gas torch, grinding, or plasma cutting are chosen according to the type of steel or other metal in use.

4. End Preparation:

Beveling and fit-ups are completed following an approved specification and WPS.

5. Welding:

Pipe welding planning ensures all seams will be positioned and aligned correctly in the final assembly.

6. Pipe and Fitting Welding:

Pipes and fittings are supported and secured for a fit-up inspection. If passed, the joints are welded.

7. Details Marking:

Various identifying details of the piping system, inspection details, signature, and welding date are marked near joints. The pipe spool number is marked with a paint marker and aluminum tag.

8. Heat Treatment:

Preheating and PWHT may be completed depending on project requirements.

9. Inspection:

Non-destructive testing ensures that all steps of the fabrication process have been completed and meet or exceed the project requirement and regulations.

Piping that passes is released for painting or construction. Piping that does not pass must be repaired and reinspected. Piping that is to be painted will require another inspection prior to being released.

Benefits Of Pipe Spool Drawing

- Visualization: Pipe spool drawings provide a visual representation of the piping system, allowing designers, engineers, and fabricators to visualize how the pipes will be laid out and interconnected. This helps in identifying potential clashes or interferences with other equipment or structures before the fabrication process begins.

- Accuracy: Pipe spool drawings are typically created using computer-aided design (CAD) software, ensuring accuracy and precision in the design. The drawings include detailed measurements, pipe specifications, and accurate representations of fittings, valves, and supports. This level of detail helps in ensuring that the fabricated spools will fit together correctly during installation.

- Fast Fabrication: Pipe spool drawings serve as a reference for fabricators during the manufacturing process. The drawings provide all the necessary information, such as pipe lengths, diameters, angles, and welding details, enabling fabricators to efficiently cut, bend, weld, and assemble the pipes into spools. This helps to streamline the fabrication process and minimize errors.

- Clash Detection: Clash detection is a crucial benefit of pipe spool drawing. By creating detailed 3D models of the piping system and other equipment, clash detection software can identify potential clashes or interferences between different components. This allows designers to make necessary adjustments and ensure that the pipes can be installed without any conflicts with other structures or equipment.

- Cost and Time Savings: Accurate pipe spool drawings help to minimize rework and modifications during the fabrication and installation phases. By identifying clashes or interferences early on, costly on-site changes can be avoided. Additionally, efficient fabrication based on precise drawings reduces material waste and labor hours, resulting in cost and time savings for the project.

- Improved Communication: Pipe spool drawings serve as a common reference point for all stakeholders involved in the project, including designers, engineers, fabricators, and installers. The drawings provide a clear understanding of the piping system design, reducing misinterpretation or confusion. Effective communication facilitated by detailed drawings helps to ensure that everyone is on the same page and working towards the same goal.

Faqs

E3d, SP3D, Cadworks and Autocad.

A pipe spool fabrication drawing is like a special picture that shows how to make a pipe. It includes important details about the pipe, like how big it should be, what material to use, and how to connect it with other pipes. It also tells the people making the pipe if they need to weld it, use special parts, or add extra support.

When you look at a pipe spool fabrication drawing, it’s important to pay attention to a few important things. Look for the sizes of the pipe, the kind of material it should be made from, and any special instructions. You can also see how the pipe should be connected with other pipes and if it needs any extra parts or support.

Pipe spool fabrication drawings are like a guide for the people making the pipe. They look at the drawing and follow the instructions to make sure the pipe is built correctly. The drawing helps them know the right size, the right material to use, and how to connect everything together. By following the drawing, they can make sure the pipe is strong and works well.

Yes, there are rules that people follow when making pipe spool fabrication drawings. These rules are important to make sure the pipe is safe and works properly. Different countries and industries may have their own set of rules. Some important rules are about how to weld the pipe, what materials to use, and how to make sure the pipe is strong. These rules help keep everything consistent and make sure the pipe is made correctly.