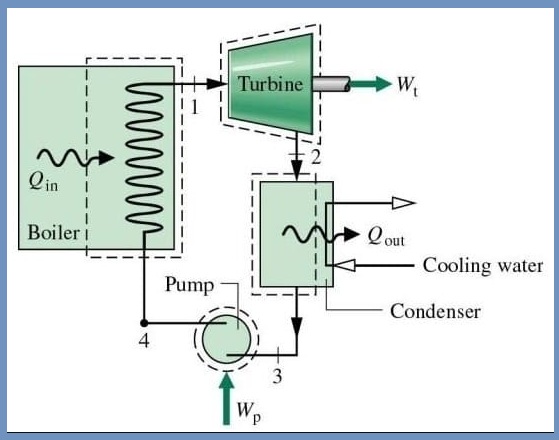

The Rankine cycle is the most widely used thermodynamic cycle in various power plants including nuclear power plants and coal-fired power plants. The Rankine cycle represents the process through which a reciprocating steam engine or steam turbine extracts mechanical energy from a running medium because it flows between a heat accumulator and a heat source.

In easy words, a Rankine cycle describes how a heat engine which includes a steam engine extracts thermal power from a heat supply and makes use of this power to generate electricity. These heat sources can also additionally have combustion of ethanol, biomass, oil, herbal gas, coal, or nuclear fission process, etc. In the nineteenth century, William John Macquorn Rankine invented the Rankine cycle.

The thermal energy extraction ability of a Rankin engine relies upon the temperature of the heat sink and the temperature of the heat source. The larger the temperature difference, the more mechanical energy the engine can obtain from thermal energy, in step with Carnot`s theorem.

What is Ideal Rankine Cycle

In the case of a steam cycle, if the operating medium travels through different components of the engine without frictional pressure or irreversible loss, the cycle is called the ideal Rankine cycle.

The Rankine cycle is the primary work cycle for all power plants where the hydraulic fluid changes continuously from liquid to steam and from steam to liquid. This is a theoretical cycle in which thermal energy is transformed into useful work.

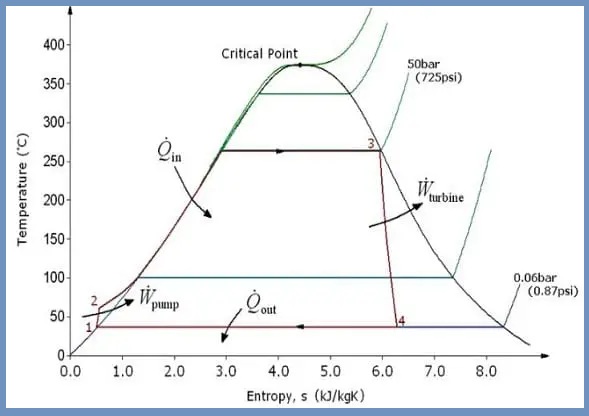

The T-S diagram of the Rankine cycle is proven below. This will assist you to recognize how the Rankine cycle works.

There are various stages involved to complete the Rankine Cycle. I have described the complete procedure of its completion process.

- Isentropic compression (1-2): At this stage, the pump carries water or another working medium from the body of water (such as sewers or tanks) to the boiler. The pump requires a small amount of energy to pump first. The liquid is pumped by increasing the pressure of the liquid, but the entropy of the liquid remains the same. For the initial pump, the work done by the pump is as follows:

- Constant pressure heat addition process (2-3): An external heat source supplies heat to the boiler while water is supplied to the boiler. The boiler heats the water at constant pressure and converts it into dry saturated steam (steam). The enthalpy of the liquid changes while the pressure remains constant.

- Isentropic expansion (3-4): After a constant pressure input heat process, the steam enters the turbine section and expands there. When the steam expands, it collides with the turbine blades and converts the thermal energy of the steam into rotational energy (mechanical work). As the turbine blades rotate, so does the crankshaft, which causes the generator coil to rotate further. When the coil rotates in a magnetic field, it produces electricity. Throughout this process, the pressure and temperature of the steam will drop. This can lead to condensation.

- Constant pressure heat release method (4 to 1): Steam enters the condensation tank after the expansion process. In this condensation process, the vapor is condensed into a saturated liquid. During this process, the vapor releases heat, but its hydraulic pressure remains the same.

In an ideal Rankine cycle, turbines and pumps operate under isentropic conditions. This means that turbines and pumps do not produce entropy. They only improve the performance of the cycle. The Rankine cycle prevents hydraulic fluid from entering the superheated steam region after expansion in the turbine, reducing the energy consumed by the condenser.

Actual Rankine Cycle or Non-Ideal Rankine Cycle

In a real Rankine cycle (or a real power plant), the turbine expansion process and the pump compression process cannot be performed under isentropic conditions. In easy words, these are irreversible processes, and the internal energy (entropy) of the liquid increases during these processes.

This cycle increases the required power of the pump to some extent and reduces the power produced by the turbine.

The formation of water droplets controls the efficiency of the steam turbine. When the water droplets condense, they collide with the turbine blades at high speed. This causes erosion and pitching on the turbine blades. This erosion and pitting gradually reduce the life and productivity of turbine blades. The easiest way to solve this problem is to overheat the steam.

As you can see in the above given T-S diagram of the Actual Rankine Cycle, state 3 is at the boundary of the two-phase region of water and steam. After expansion, the steam changes to a very moist form. When steam is overheated, state 3 moves to the right (and up) in the above figure and generates dry steam after expansion.