Table of Contents

Introduction

The refrigeration cycle is a thermodynamic cycle that is used to draw-out heat from a particular space that you want to cool. It is also referred to as the heat pump cycle. The refrigeration cycle is specifically designed for refrigeration systems, air conditioning systems, and heat pumps. The heat pump is a mechanical device for transferring heat from a low-temperature space to a high-temperature space.

How Does Refrigeration Cycle Work?

There are five processes that are essential to complete the refrigeration cycle.

- Suction

- Compression

- Condensation

- Throttling

- Evaporation

1) Suction process:

First, the refrigerant is introduced into the compressor chamber of the compressor. Refrigerant enters the compression chamber in the form of steam.

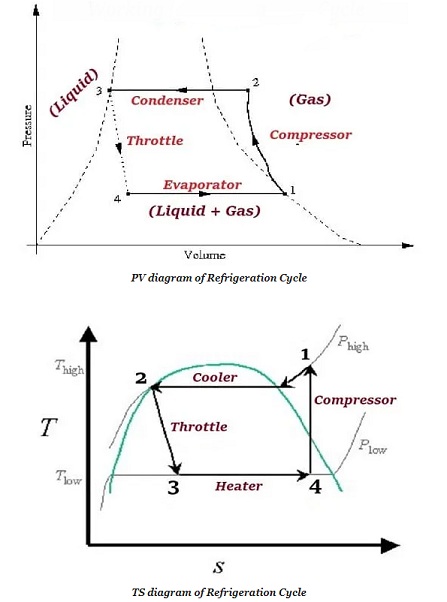

2) Adiabatic compression (1-2):

The compressor has a piston that moves up and down in the compression chamber. When the refrigerant enters the compression chamber, the inlet and outlet valves close and the piston compresses the refrigerant. Due to the compression process, the temperature of the steam refrigerant rises from T1 to T2 and the pressure rises from P1 to P2. Line 1 to 2 of the above-given graph represents this process. After the compression process, the compressed refrigerant enters the condenser.

3) Condensation Process (2 to 3):

Line 2 to 3 represents the condensation process. As the compressed refrigerant enters the condenser, the condenser condenses the compressed vapor refrigerant at constant pressure. During the condensation process, the compressed refrigerant transfers its heat to the hot reservoir. This heat transfer process converts the refrigerant vapor into a liquid state. In the process, the enthalpy and volume of the refrigerant decrease. However, the refrigerant pressure remains the same throughout this process. After this process, the liquid refrigerant is supplied to the throttle valve for further processing.

4) Squeeze process (3-4):

After the condensation process, the liquid refrigerant is pushed into the throttle valve. As the refrigerant enters this valve, it expands; due to that, the pressure and temperature of the liquid refrigerant reduce. However, the volume and enthalpy of the refrigerant increase. After this process, the liquid refrigerant still remains in a liquid state; due to that, we need to pass it from the evaporator to convert the liquid into a vapor state.

5) Evaporation Process (4 to 1):

Line 4 to 1 of the above-given PV diagram and TS diagram of the refrigeration cycle represent this process. The evaporator is connected to a cold reservoir. When the low-pressure, low-temperature liquid refrigerant enters the evaporator, the refrigerant absorbs heat from the cold reservoir and converts it into a vapor state. Refrigerant volume and enthalpy increase while keeping pressure and temperature constant. After this evaporation process, the refrigerant vapor is sent back to the compressor and the entire cycle is repeated.

Different Types of Refrigeration Cycles

- Stirling Cycle

- Reversed Carnot Cycle

- Vapour Compression Cycle

- Vapor Absorption Cycle

- Gas cycle

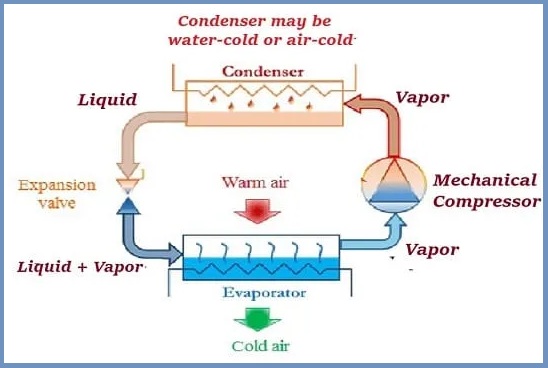

Parts of a Refrigeration System

- Compressor

- Condenser

- Expansion Valve

- Evaporator

See the below image to understand it better.

Advantages of Refrigeration System

- This cooling uses air as the refrigerant.

- Refrigerants are always available in the atmosphere.

- Refrigerant is free and ready to use.

- This cooling has a very simple design and structure.

- Air is non-corrosive, non-flammable, and non-toxic.

- There is no danger of fire due to refrigerant leakage from the piping.

- This refrigerant can also use cold air as the refrigerant.

Drawbacks of Refrigeration System

- This cooling system has a high running cost. “

- The O.P. of the air refrigerant is low. Than other types of refrigerants.

- Air cooling systems use more refrigerants than other refrigerants.

- This system has large and bulky parts.

Applications/Uses of Refrigeration System

- Central air conditioner

- Surgical and medical assistance

- Freeze food

- Metal processing

- Chemical industry

- Industrial air conditioner

- Food transportation

- Make ice cream