A steam turbine is a mechanical device that converts the thermal power of steam into mechanical work in the form of rotational energy. This turbine is known as a steam turbine because it uses steam as the hydraulic fluid. The first steam turbine was discovered by Sir Charles A. Parsons in 1884.

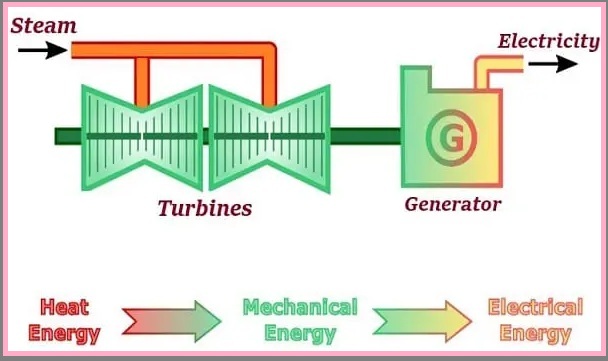

In this turbine, the mechanical work is generated by the turbine shaft. This shaft is coupled to a steam generator that converts the mechanical power of the shaft into electric power.

Steam has one advantage over water. That is, the amount of steam expands very quickly. The speed of a steam turbine is directly proportional to its output. Therefore, if you want to achieve the best performance, the steam turbine must operate at the highest speed. Wheel turbines cannot rotate as fast as steam turbines. Maximum efficiency can be achieved by utilizing the kinetic energy of steam. These turbines have many advantages over other types of turbines. Produce cheap electricity and steam energy does not pollute the environment. For these reasons, these turbines have replaced reciprocating engines as prime movers for large power plants. Steam turbines operate according to the basic principles of thermodynamics. That is, as the steam expands, its temperature drops.

Table of Contents

How Does Steam Turbine Work?

The operating principle of a steam turbine is very simple. Steam turbines operate on the basic principles of the Rankine cycle.

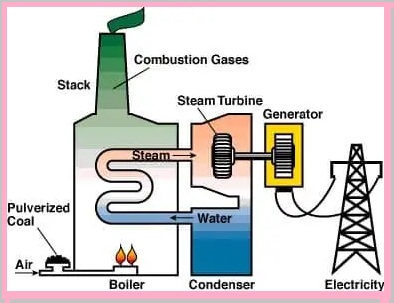

In the operation of a steam turbine, water is first pumped from an external source (eg, river, sea, or canal) to the boiler section. It then heats the water in the bowler to a very high temperature, turning it into supersaturated vapor. In a boiler, the amount of steam generated differs depending on the heat of combustion, volumetric flow rate, and heat transfer surface. When the boiler produces steam, the steam is sent to the turbine section. In fact, in these turbines, the pressure energy of the steam is expressed in K.E. After passing the steam through the nozzle, the was converted.

When steam hits the rotor blades, it creates ram pressure on the shaft and rotor blades. As a result, both the shaft and the blade begin to rotate in the same direction. In this process, the thermal energy of the steam is converted into the rotational energy of the rotor blades and the rotor begins to rotate.

The shaft is coupled to the turbine rotor. The shaft receives rotational energy from the rotor and begins to rotate. A generator called the

steam generator is connected to the shaft by a coil. The shaft rotates the generator coil in a magnetic field. When the coil rotates in a magnetic field, a current is generated and flows through the wire. Due to the simplicity of the structure of these turbines, the vibration is much lower than other engines of the same speed.

Components/Parts of a Typical Steam Turbine

- Housing

- Rotor blades

- Rotor

- Governer

- Turning Gears

- Sentinel Valve

- Nozzle ring and reversing blade assembly

- Labyrinth Seal

Steam Turbine Efficiency

Many factors have an effect on the steam turbine`s performance which includes the dimensions and sort of the turbine in addition to the temperature, and strain of the inlet steam and exhaust. It additionally relies upon the go with the drift charge of steam.

Steam mills are high-quality and suitable for huge thermal power plants. There are one-of-a-kind sizes of steam mills as much as 1.5 Gigawatt for producing electricity.

You can calculate the efficiency of a steam turbine using the formula given below.

How to Improve the Efficiency of Steam Turbines

There are several ways to improve the efficiency of steam turbines, some of which are listed below.

- Overflow tape can also be used to reduce choke loss.

- Friction loss can be reduced by using highly efficient blades/nozzles.

- The exhaust baffle can be used to reduce the pressure inside the exhaust housing.

- The specific characteristics used in a particular application are generally based on the trade-off between capital investment and the cost of steam generation over the life of the turbine. So this is a method of optimization.

- In a water preheater, the turbine extracts the expanded steam under certain conditions. After extraction, this steam is used to heat the water just before it is sent to the turbine. In a water preheater system, the energy from the extracted steam is returned to the system and the loss from the cold source is much less than in a simple Rankine cycle. In addition, this extraction process is completed in various phases. Theoretically, the efficiency of a power plant is directly proportional to the number of steam extraction stages. The more steam extraction stages, the more efficient the power plant.

Pros

- This is a type of rotary heat engine, especially suitable for driving generators.

- Piston engines have lower thermal efficiency than steam generators. The power-to-weight ratio is much higher than that of a reciprocating engine.

- Compared to reciprocating engines, these turbines have few rotating parts.

- These turbines are ideal for large thermal power plants.

- There are different sizes of turbines up to 1.5 GW for generating electrical power.

- Generally, steam contains a large amount of enthalpy (especially in the form of heat or vaporization). It means steam has less mass flow as compared to gas turbines.

- Steam turbines are more reliable, especially in applications that require continuous high performance.

- The electricity produced by a steam turbine has a relatively low cost.

Cons

- The initial cost is high.

- In partial load operation, the efficiency of this turbine is lower than that of the reciprocating engine.

- It has a longer starting time than a gas turbine and longer than a reciprocating engine.

- Compared to reciprocating engines and gas turbines, it is less responsive to changes in energy demand.

Uses

- The initial cost is high.

- In partial load operation, the efficiency of this turbine is lower than that of the reciprocating engine.

- It has a longer starting time than a gas turbine and longer than a reciprocating engine.

- Compared to reciprocating engines and gas turbines, it is less responsive to changes in energy demand.