A kind of valve which makes use of a hollow, turning, and perforated ball to govern the fluid glide is called a ball valve. The ball of the valve has a hollow inside the middle. This ball unit is among the 2 seats. The role of the ball is managed thru an actuator or wrench handle.

The ball valve has the capacity to govern, guide, direct and modulate the glide of various fluids which include liquids, gases, and vapors.

The ball valve opens or closes the fluid flow by turning the wrench handle 90 degrees clockwise or counterclockwise. It begins to flow when the ball hole becomes parallel to the direction of fluid flow. When turning the wrench handle counterclockwise to 90 degrees, the ball stops the flow of liquid.

Ball valve with high reliability and long service life. You can operate them pneumatically, electrically, or manually.

These valves ensure long-term reliable sealing, even in the case of dirty liquids. They are more resistant to harmful liquids than other valves. Therefore, they are preferred over globe valves and gate valves.

For specific applications, the ball valve can also be used as a check valve. These valves have a solid globe to prevent unwanted backflow of liquid. This type of ball valve is not widely known because the accuracy of liquid flow control is not enough compared to other types of check valves.

Table of Contents

How Does Ball Valve Work?

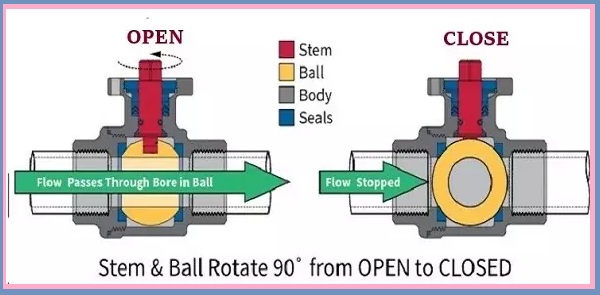

Ball valves are very similar to butterfly valves. There is a sphere with a drill hole in the center. The position of the ball hole determines whether the flow is open or closed. The ball is connected to the shaft, which is also connected to the wrench handle or actuator.

The ball valve works as follows.

- To start the fluid flow, rotate the actuator about 90 degrees clockwise. When it rotates, the stem rotates. The stem rotates the ball. When the hole in the

- ball matches the flow of fluid, and the flow through the valve begins.

- To stop the flow, the actuator rotates about 90 degrees counterclockwise and the stem also rotates counterclockwise. When the ball rotates counterclockwise about 90 degrees, the liquid flow stops completely.

- To limit the flow, the ball is kept partially open and partially closed. If a partially open valve is left in a high-pressure descent for an extended period of time, the soft sheet tends to flow around the end of the ball orifice, which can permanently lock the ball in its place.

Different Types of Ball Valves

- Standard Port Valve

- V Port Valve

- Multi-Port Valve

- Reduced-Port Valve

- Full Port Valve

- Single Body or One-Piece Ball Valve

- Two-Piece Valve

- Three Piece Valve

- Top Entry Valve

- Side Entry Valve

- Welded Body Valve

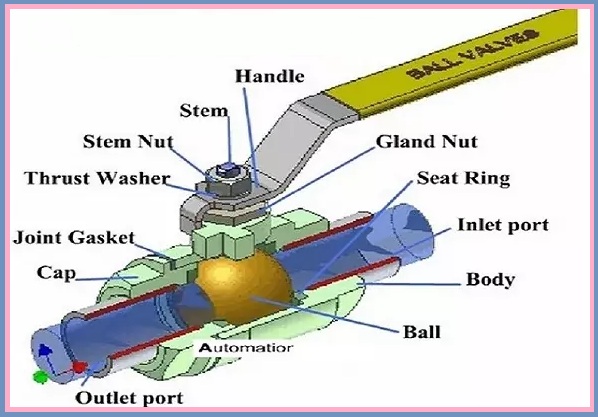

Parts/Components of Ball Valve

- Ball

- Stem

- Handle/Actuator

- Valve body

- Valve seats

- Seat ring

- Packing

- Bonnet

For better understanding, I also attached an image. (See below image).

Pros

- Ball valves have a simple design.

- It has a relatively small mass and is lighter than a gate valve.

- Easy to repair and disassemble.

- The stem seal of this valve cannot be broken easily.

- In these valves, the fluid has a low resistance.

- Pneumatic valves have one of the lowest fluid resistance of all valves.

- It has a quick duty cycle and easy operation.

- They have high flow and low-pressure drop.

- It ensures a perfect seal.

- Open and close quickly.

Cons

- It has higher wear than gate and globe valves when used for slurry fluids.

- The holes around the ball and seat make it unsuitable for mud applications.

- The sludge tends to stick or solidify in the cavity, greatly increasing the operating torque of the valve and causing the valve to fail.

- It opens and closes too quickly, causing overpressure and hammer problems.

- Abrasive solids suspended in a liquid or gas stream can damage the valve seat and ball surface if the ball moves over the base during cleaning.

- These valves are difficult to clean (except for the inlet design valves).

- Ball valves have a high wear problem.

- These valves with the drive process must be installed vertically.

- This is not ideal for flux tuning.