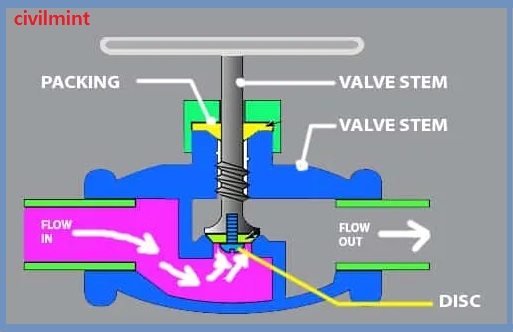

A globe valve is a very popular type of valve that controls the flow of fluid through a disc or plug. The name of the globe valve comes from a sphere consisting of two halves. The internal partition helps to separate the halves. A tight ring sheet is attached to the sphere.

Poppets play a major role in regulating fluid flow. This plug or disc is connected to the shaft. This shaft is also connected to the handwheel.

For manual valves, the operator turns the handwheel to open and close the valve.

Turn the handwheel to open and close the valve and the cone will move perpendicular to the valve seat. This movement of the poppet creates an annular space between the seat insert and the poppet, which closes slowly when the valve closes. This characteristic of the isolation valve makes it ideal for flow throttle applications. The main function of the shut-off valve is to ensure reliable throttle and shut-off.

The main drawback of the gate valve is that it has a higher pressure drop than the gate valve.

The internal component is mounted in the valve cavity, resulting in a complex design. These valves have the ability to change the flow rate and direction of flow, causing large pressure losses.

The isolation valve is used in various pipelines to regulate the flow of liquids.

Table of Contents

Working Concept of a Globe Valve

The globe valve is a one-way valve. Can only be installed in one direction. There are handwheels, discs or cones, and spindles. Shut-off valves are used to regulate, start and stop the flow of liquid.

The globe valve works as follows:

- The operator turns the valve handwheel to open, close, or adjust the flow rate.

- The handwheel is connected to the stem, which is also connected to the valve head.

- To block or reduce fluid flow, the operator turns the handwheel clockwise and the handle transmits downward movement to the shaft.

- When the stem receives the movement of the handwheel, it also moves down and pushes down on the valve disc.

- This downward movement of the valve disc eventually fits between the two seats of the valve, stopping the flow of fluid.

- To open the valve, the operator turns the handwheel counterclockwise.

- In this situation, the stem pulls on the valve disc to remove the disc from the two valve seats.

- To throttle the flow, the operator turns the handwheel so that the valve disc partially opens and closes.

Functions of Globe Valve

- The main function of these valves is to regulate, start or stop the flow of fluid.

- They are specially designed to control fluid flow and their functionality is not limited to shut-off functionality.

- These attributes distinguish some of the widely used valves, such as gate valves and ball valves.

Pros

- This type of valve has excellent closing capacity.

- Maintenance is easier than ball valves.

- The structure is simpler than the ball valve.

- These valves are ideal for throttled flow.

- They have a shorter stroke than gate valves.

- Globe valves operate faster than gate valves.

Cons

- These valves have an excessive-strain loss.

- They require excessive pressure to seal the valve.

- Obstructions and channel discontinuities can reason a massive strain drop.

- Pulsations and shocks in massive excessive-strain pipes can harm inner ornamental parts.

- They have excessive weight.

- They have an extra complicated creation than the gate valves.

- These valves generate very extra noise than the gate valves.

- They have excessive upkeep and set-up expenses than gate valves.

- More massive or extra electricity is needed to open and make noise at some point of operation.

- These valves have an excessive-strain loss in comparison to the ball valve and gate valve.

- You can set up it in only one direction.

Uses

- Poppet valves are used in water cooling systems.

- It is used in chemical supply or water supply systems.

- Shut-off valves are used in pumps and compressors.

- It is also used in exhaust and condensate extraction systems.

- These types of valves are used in heater drains, main steam vents, and drain systems.

- These are widely used in the plumbing industry.