Babcock and Wilcox boiler is external combustion, solid fuel combustion, horizontal drum shaft, high-pressure boiler, fixed, multi-tube, natural circulation, and natural draft boiler.

It is a kind of water tube boiler. This boiler is used in applications that require high-pressure steam. This high-pressure steam is used to generate electricity in a hydroelectric power plant.

In 1967, George Herman Babcock and Stephen Wilcox invented this boiler. Therefore, from the name of the discoverer, it is known as the Babcock & Wilcox cauldron.

This is an external combustion water tube boiler. It is used to generate a large amount of high-pressure steam. In this boiler, the electric current controls the circulation of water.

Table of Contents

How does Babcock and Wilcox Boiler work?

Step by step procedure of this type of boiler is as follows.

- First, water is supplied to the water drum, and solid fuel is placed on the grate.

- Fire doors are used to provide fire to initiate the burning of fuel.

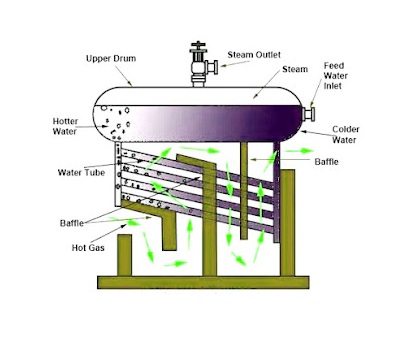

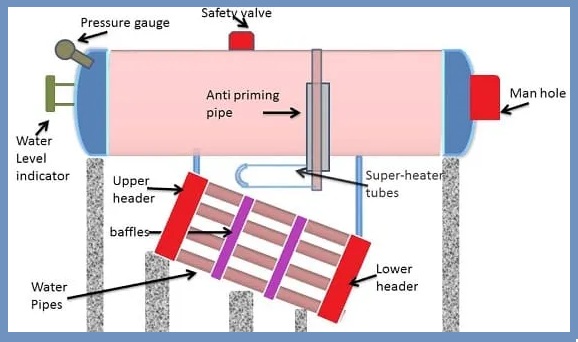

- This shell has an ingest header and a down take header. The uptake and downtime headers have multiple holes through which the sloping water pipes pass.

- The feed pump pumps water from the drum through the down take header to the water pipe.

- Hot flue gas is generated as the fuel begins to burn on the grate.

- When hot flue gas comes into contact with the water pipe, it transfers heat to the water in the water pipe.

- When water is heated, it turns into steam.

- Convection is used to maintain the circulation of water, and this process is called natural circulation.

- When steam is generated, it rises through the intake manifold and collects on the boiler drum. The boiler drum has an anti-priming tube. This tube helps separate moisture from the steam.

- After this steam separation process, dry steam is supplied to the superheater. As the dry steam flows from the anti priming tube to the superheater, the superheater raises the seam temperature to the required level and turns it into superheated steam.

- When the steam turns into an overheated state, it is sent to the steam isolation valve.

- The steam isolation valve sends superheated steam to the steam drum or steam turbine to generate electricity.

Components of Babcock and Wilcox Boiler

The main parts of this boiler are as follows.

- Water Level Indicator

- Steam Space

- Water space

- Water Drum

- Superheater

- Down take Header

- Dampers

- Furnace

- Uptake Header

- Feed Check Valve

- Water Tubes

- Mud Box

- Baffle Plates

- Fire Door

- Grate

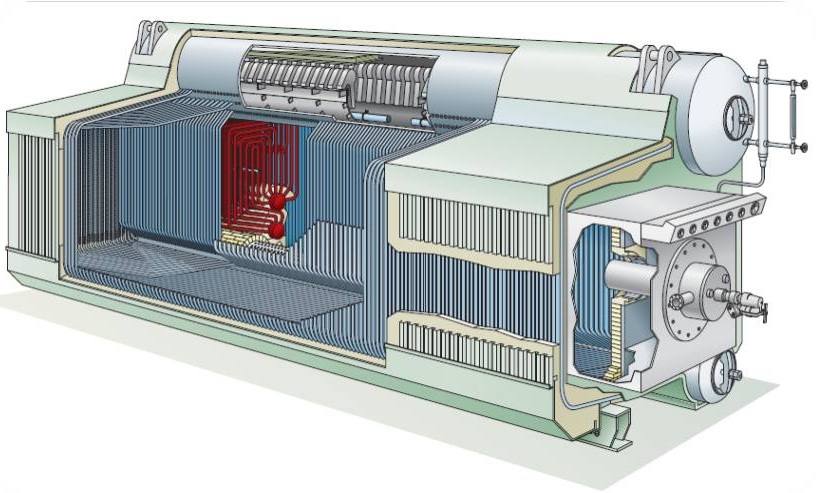

I also represented these parts of the boiler in the figure given below.

Pros

- These types of boilers are capable of producing up to 2000-40,000 kg / h of steam.

- Babcock boilers and Wilcox boilers have a smaller footprint than other types of water-tube boilers.

- The overall efficiency is high.

- The size is small.

- Easy to clean and repair.

- Easy to install.

- This is the only boiler that produces a large amount of heat in a hydropower plant.

- This boiler is easy to maintain. The loss due to drought is small.

Cons

- The maintenance effort is very high.

- This type of boiler is not ideal for sediments and impure water.

- When water becomes contaminated and settles, scale builds up on water pipes, which can overheat and explode. Therefore, water needs additional treatment before it enters the boiler.

- These boilers require a continuous water supply for proper operation. In this case, the boiler will overheat if water is not added even for a short time. During the Babcock & Wilcox boiler process, the water level needs to be monitored very carefully.

Applications and Uses of Babcock and Wilcox Boiler

- Babcock- Wilcox boilers are most commonly used to generate high-pressure steam in hydropower plants.

- These boilers are used to generate large amounts of electricity in hydropower plants.