The scroll compressor is a specific type of compressor in which two or more two scrolls are used to compress the working fluid.

These coils move in a circular motion instead of an up and down motion like the action of pistons in reciprocating compressors.

One scroll rotates and the second scroll remains stationary. Fluid enters the compressor and is trapped between two scrolls. The compression process begins when the rotatory scroll rotates.

There are lots of similarities between screw compressors and scroll compressors in terms of design and function. The working of the scroll compressor is very similar to the screw compressor. It works quietly and smoothly.

These types of compressors are more efficient and reliable than piston compressors. Therefore, scroll compressors are most commonly used in HVAC systems. One of the main advantages of the Scroll Compressor is its lower torque and fewer rotating parts than the reciprocating compressor. These compressors can be used in a variety of ways to meet homeowners’ needs for economy, comfort, and efficiency.

Table of Contents

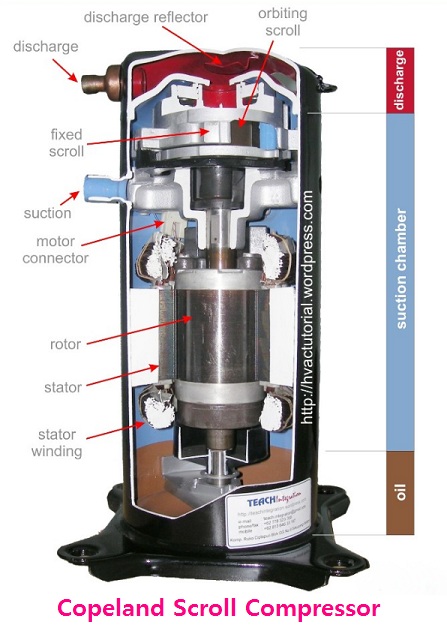

What is Copeland Scroll Compressor?

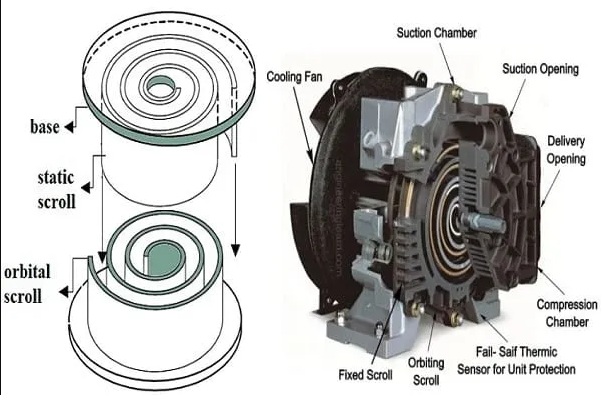

Copeland scroll compressors operate with a coil that rotates around a path defined by a corresponding static coil. The static coil is attached to the compressor body while the orbital coil is coupled to the crankshaft. The trajectory of motion creates a series of air pockets that move between the two reels. On the outside of the reels, the bags draw air in and then move it to the center of the reel, where it is discharged. As the gas moves towards the center of the potential, the temperature and pressure rise to the desired discharge pressure.

How Does Scroll Compressor Work?

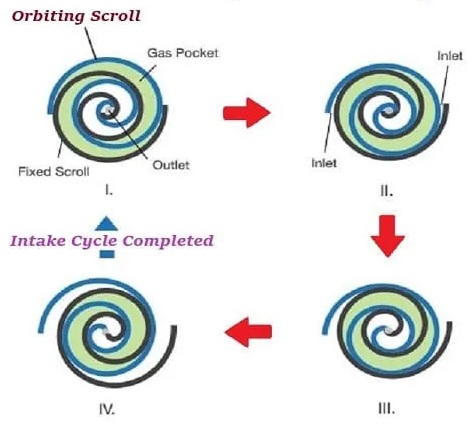

Scroll compressors work on the principle of positive displacement. It has two scrolls, one rotates while another remains stationary. In a typical Scroll compressor, the moving scroll rotates 180° with respect to the stationary scroll. In this way, these scrolls operate with each other.

The movable scroll is connected to the crankshaft and the fixed scroll is connected to the compressor body. A generator or electric motor is used to drive the crankshaft. When the drive motor powers the crankshaft, the crankshaft begins to rotate. When the crankshaft rotates, its movement is transmitted to the moving scroll to rotate it. The movement of the moving scroll creates a pressure difference between the internal and external pressure of the compressor.

The pressure difference creates a suction force that carries air from the external air reservoir to the compressor. The sucked air is trapped between the moving and stationary scrolls. This trapped air cannot flow directly from the suction side to the discharge side. It can be moved only by scrolling. As the movable scroll moves, the trapped air gradually moves toward the center of the compressor, reducing the amount of air and compressing it.

Finally, the compressed air reaches the center of the assembly and the compressed air is expelled through the connection.

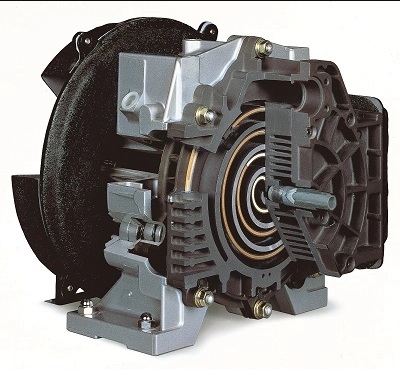

Arrangement of Scroll Compressor

Scroll compressors have two mesh rolls to pressurize, compress, or pump liquids (such as liquids or gases). The design of the spiral can be a hybrid curve, an Archimedean spiral, or an invariant curve. Normally, one rope is at rest while the other moves eccentrically without compressing, pumping, trapping, or rotating pockets of liquid between the ropes. The movable scroll is connected to the crankshaft while the static scroll is attached to the compressor housing. Static scrolling guides the movement of the moving scroll.

You can prevent leaks in the axial space by using a sealing gasket. Insert this spacer into the groove of the two ends of the winding. These seals also reduce friction and you can easily replace them when they wear out.

Some types of scroll compressors use pressurized exhaust gas to bring the two coils together. This method eliminates the need for end seals and improves the seal used.

The compressor’s hose also produces extreme vibration where the Archimedes screw acts as a peristaltic pump that acts like a toothpaste tube. Such a compressor has a lubricant-filled housing that helps prevent wear on the outside of the compressor hose and aids heat dissipation by using a reinforced tube commonly known as a “tube”. This type of pump is also known as a “peristaltic pump”.

The peristaltic pump has a low manufacturing cost because the moving parts of this pump do not come into contact with the liquid. They have low maintenance costs as they have no fittings and valves.

Types of Scroll Compressors

Three types of scroll compressors are used commonly:

- Single-stage Compressor

- Two-stage Compressor

- Variable Capacity Compressor

Let us have a look at these scroll compressors.

1. Single-stage Compressor

Single-stage scroll compressors are most commonly used in domestic heating and cooling applications. These scroll compressors have a simple structure. They have a low cost. However, you can only run them at a specific speed. They are capable of effectively heating or cooling your building.

2. Two-stage Compressor

Two-stage compressors operate at two different speeds. These compressors are capable of bringing their heating or cooling capacity closer to the exact needs of the home. The two-stage compressor is capable of running at a slower, more efficient speed, removing excess moisture from the air while saving energy. You can also set the compressor to run at full capacity if you want to stabilize the temperature. These compressors are more efficient than single-stage compressors.

3. Variable Capacity Compressor

Instead of operating in one or two stages, variable capacity compressors allow you to adjust capacity in small increments over a wide operating range, giving you excellent control over indoor temperature and humidity levels. In this way, you can adjust the heating and cooling system very precisely; The whole house can be kept at the right temperature and energy can be saved at the same time.

Nonetheless, variable capacity compressors are more expensive than single-stage or two-stage compressors. The main advantages of this type of compressor are low energy consumption, reduced monthly energy bills, and almost twice the efficiency of single-stage compressors.

Pros

- Scroll compressors are more reliable because they have fewer rotating components than reciprocating compressors.

- These compressors have a compact design.

- They run quietly and don’t need spring suspension.

- Smaller than screw compressors.

- This compressor produces less noise and vibration than piston compressors.

- When the selector compressor runs at the selected capacity, the isotropic efficiency of the scroll compressor is higher than the isotropic efficiency of the reciprocating compressor. In this case, the scroll compressor is more efficient because it does not contain a dynamic discharge that causes additional acceleration losses.

- Depending on the nature of the application, scroll compressors do not require a suction valve but may or may not have a discharge valve.

Cons

- These compressors are not easy to maintain and repair.

- They cannot rotate in both directions, while reciprocating compressors can rotate in both directions.

- Scroll compressors are expensive.

Applications and Uses of Scroll Compressor

- Scroll compressors are maximum generally utilized in HVAC systems.

- They also are utilized in vacuum pumps.

- These kinds of air compressors are utilized in marine, business, and home containers.

- This compressor is used as a compressor for automobiles.

- Employed for meals and meals cooling